Geo-TH,In

Well-known Member

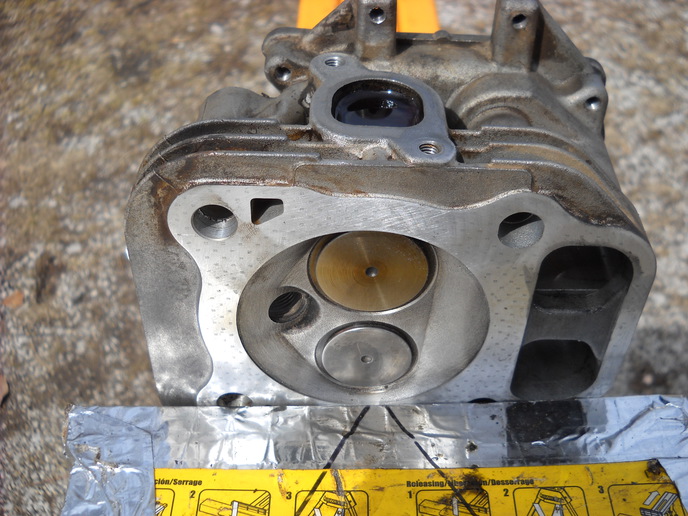

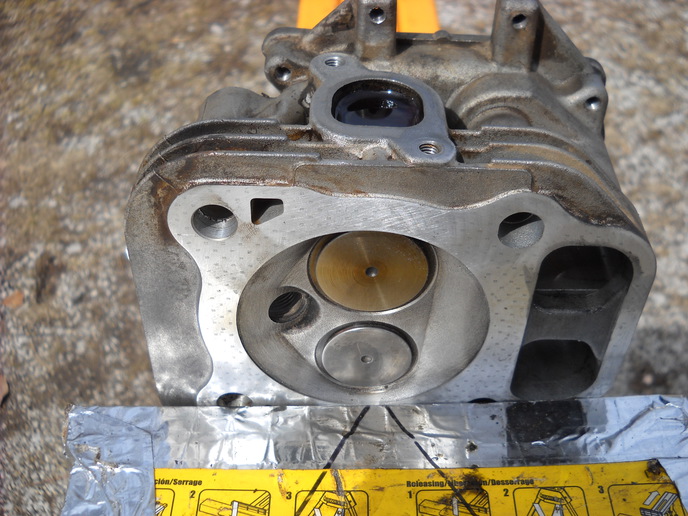

Finally got around to it, removed the head on left side #2. The small engine repair shop said I have a blown head gasket. He also recommended I replace valves while I had it apart. He wanted $100 to replace valves. I spent $10 on a gasket set for one head.

Well no blown head gasket where he said I would have one, but he was right about valves. I've read where valves seems be be a problem with kohler commands.

I used tools today that haven't seen day light in 40 years. Instead of buying new valves, I just lapped the old ones in. Then I did a leak test using K1.

I let it run at about 2400 for about 20 minutes then measured exhaust temps, both reading the same 575. That never happened in the past. The bad, dirty burning cylinder was always a good 100+ degrees cooler.

Time will tell if I solved the problem. You can see from the muffler which cylinder was burning clean and which wasn't. Keep in mind, there is only one carb for both cylinder.

This kohler has 1600 hrs and I was surprised to see very little scaring and no ridge on cylinder. If this doesn't fix the problem, I'll just run the engine until it blows.

After pulling the tractor back inside, I noticed it left oil on the concrete. Something in they hydrostatic pump area. Job for tomorrow.

Well no blown head gasket where he said I would have one, but he was right about valves. I've read where valves seems be be a problem with kohler commands.

I used tools today that haven't seen day light in 40 years. Instead of buying new valves, I just lapped the old ones in. Then I did a leak test using K1.

I let it run at about 2400 for about 20 minutes then measured exhaust temps, both reading the same 575. That never happened in the past. The bad, dirty burning cylinder was always a good 100+ degrees cooler.

Time will tell if I solved the problem. You can see from the muffler which cylinder was burning clean and which wasn't. Keep in mind, there is only one carb for both cylinder.

This kohler has 1600 hrs and I was surprised to see very little scaring and no ridge on cylinder. If this doesn't fix the problem, I'll just run the engine until it blows.

After pulling the tractor back inside, I noticed it left oil on the concrete. Something in they hydrostatic pump area. Job for tomorrow.