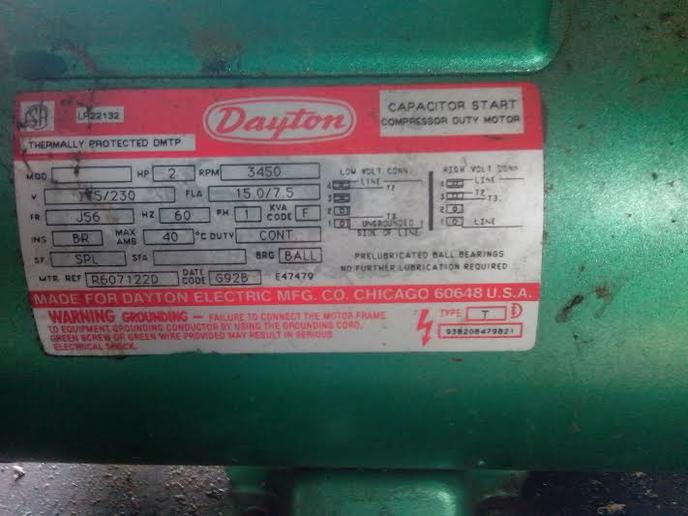

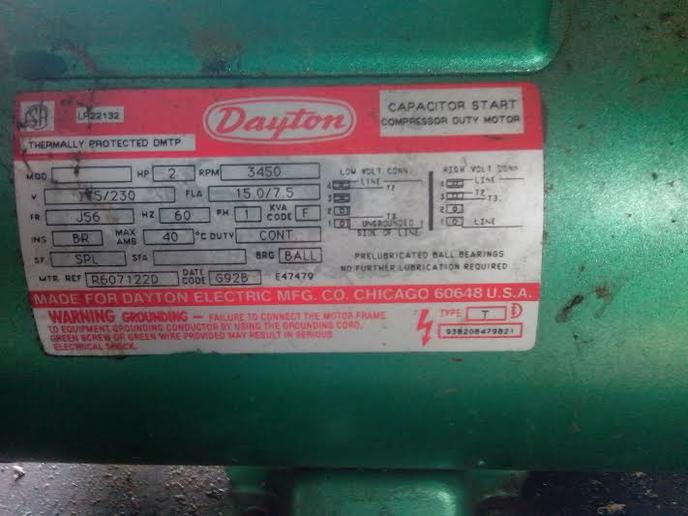

This 2hp Compressor motor works well. I want to replace the motor on my table saw, but it is running the wrong direction.

I've never had trouble with this, there is usually a diagram explaining which wire to change. Not so in this case. Were these motors non reversable? It doesnt say anything about that anywhere???

Any suggestions would be appreciated.

Thanks, Grant

I've never had trouble with this, there is usually a diagram explaining which wire to change. Not so in this case. Were these motors non reversable? It doesnt say anything about that anywhere???

Any suggestions would be appreciated.

Thanks, Grant