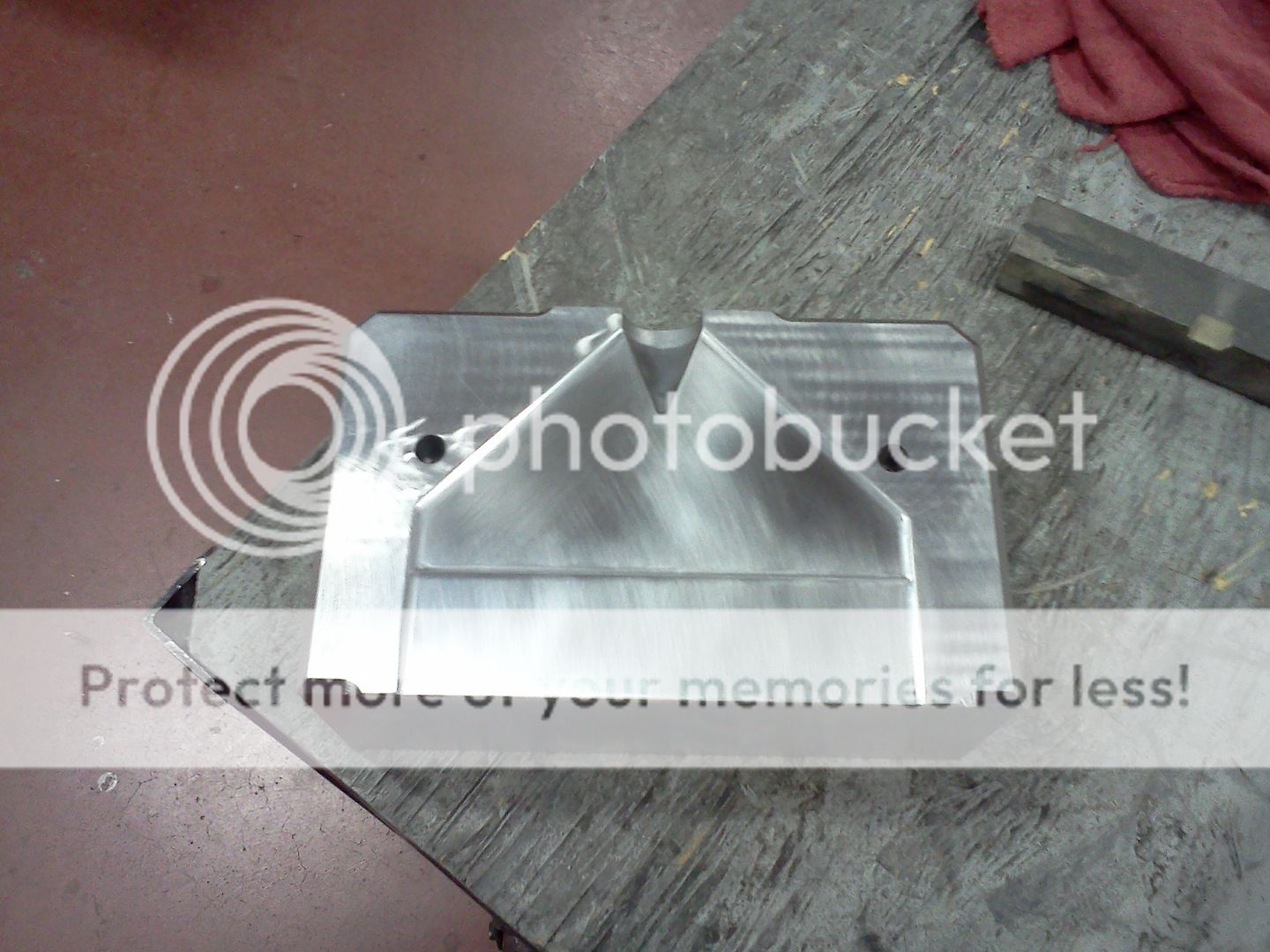

A few weeks ago I posted pictures of an adapter block I had machined and welded together. I now have pictures of it 100% complete, and plated. It just came back from the platers this morning, was still warm when I snapped the pictures.

On this next face, the hole in the middle of the counterbore turns into the 2 oval slots on the face 90* from the top.

The 4 holes are drilled clear through the block, .377" diameter

A few tiny scratches on the surface ground face, but they really show up after nickel plating.

That's a finished part. Somewhere around 11 steps start to finish, from programming to the finished nickel plated block. Lots of time and money, pretty sure this one is priced at atleast $5000. All 6 sides get something machined on them, both inside faces and then all 6 outside faces get surface ground after all the features are in. It's been touched by around 10 different guys, myself doing all of the machining, polishing, and welding. Other guys do the programming, grinding, wire edm, etc...

There are a few more in different variations coming through the shop now, some of them are 3 pc. blocks where the plastic flows in on one face, then splits into 2 and turns 90* to come out the side face from 2 holes. Others are much smaller and it goes in as 1, comes out as 4. I'll try to get some pictures of those before I weld them together this week.

Donovan from Wisconsin

On this next face, the hole in the middle of the counterbore turns into the 2 oval slots on the face 90* from the top.

The 4 holes are drilled clear through the block, .377" diameter

A few tiny scratches on the surface ground face, but they really show up after nickel plating.

That's a finished part. Somewhere around 11 steps start to finish, from programming to the finished nickel plated block. Lots of time and money, pretty sure this one is priced at atleast $5000. All 6 sides get something machined on them, both inside faces and then all 6 outside faces get surface ground after all the features are in. It's been touched by around 10 different guys, myself doing all of the machining, polishing, and welding. Other guys do the programming, grinding, wire edm, etc...

There are a few more in different variations coming through the shop now, some of them are 3 pc. blocks where the plastic flows in on one face, then splits into 2 and turns 90* to come out the side face from 2 holes. Others are much smaller and it goes in as 1, comes out as 4. I'll try to get some pictures of those before I weld them together this week.

Donovan from Wisconsin