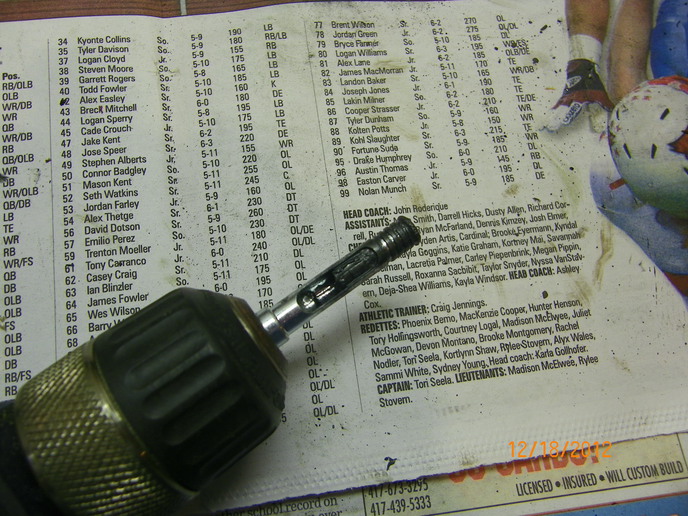

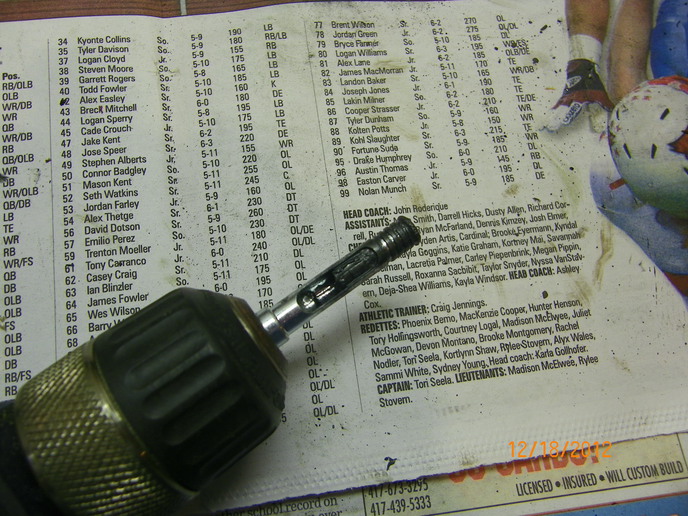

Told myself I wasn't going to break it this time but I did. How to remove the broken piece of hardened bit? Finally hit upon the idea of cutting a circle around it with a diamond tipped hole saw with just large enough ID to go around the broken piece. You see it in the pictures, the broken bit is inside the plug in the hole saw access area in the pics. Worked great. Really, you just have to go deep enough to get past the bit then tap the broken piece sideways with a punch and pick it out with needle nose or use a strong magnet. Hole saw cost me 14.00 at Lowes, you could use carbide but I went with the diamond just in case I got into the hardened easy out while drilling around it.