Finally getting around to messing with the electrical on this tractor (trying to figure out why the alternator isn't charging). Runs fine

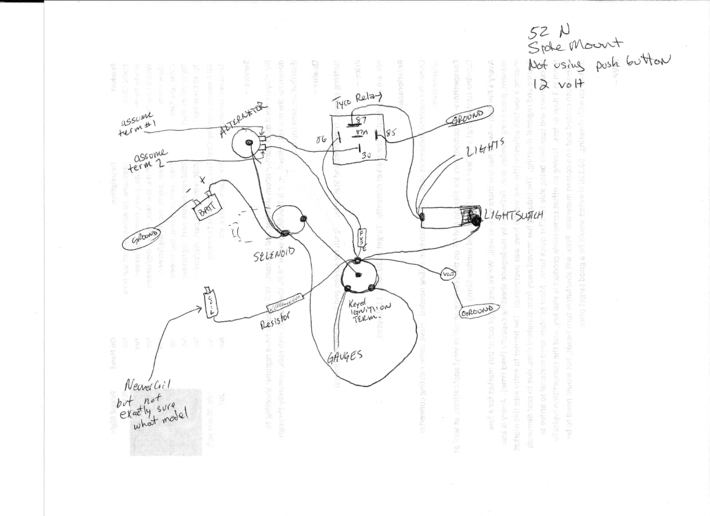

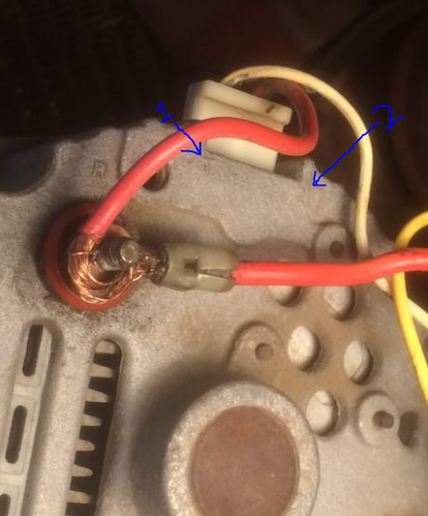

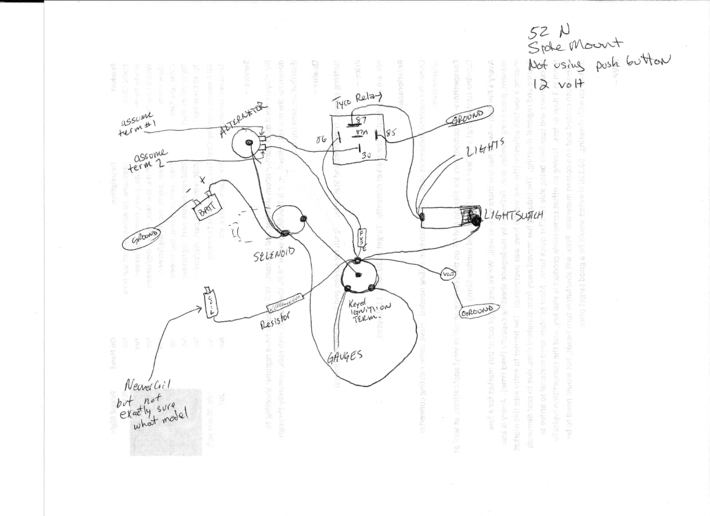

but not charging. The wiring has me perplexed. I've posted a picture of the set up.

What has me puzzled the most is the relay box, whether its needed (don't really see on any other diagrams) and if its hooked up correctly??

Also curious if I need the regulator, suppose I need to figure out the Coil ohms - if not needed, does it hurt to leave it in there?

If any of you smart fellers want to point me in the right direction, its appreciated!

Thanks!

Matt

but not charging. The wiring has me perplexed. I've posted a picture of the set up.

What has me puzzled the most is the relay box, whether its needed (don't really see on any other diagrams) and if its hooked up correctly??

Also curious if I need the regulator, suppose I need to figure out the Coil ohms - if not needed, does it hurt to leave it in there?

If any of you smart fellers want to point me in the right direction, its appreciated!

Thanks!

Matt