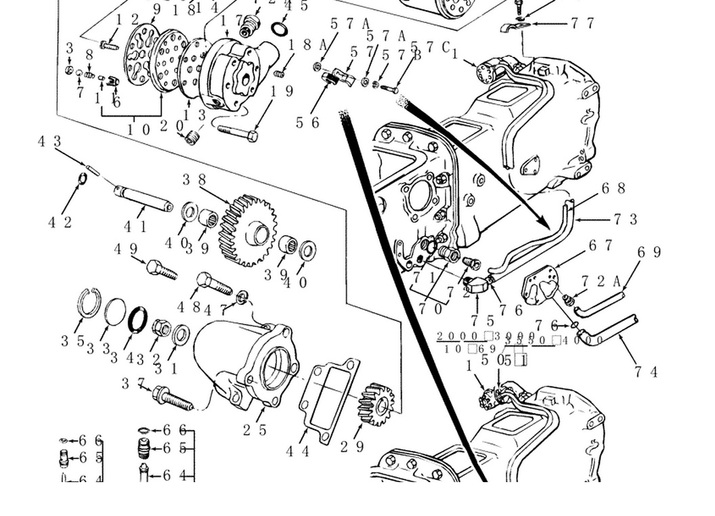

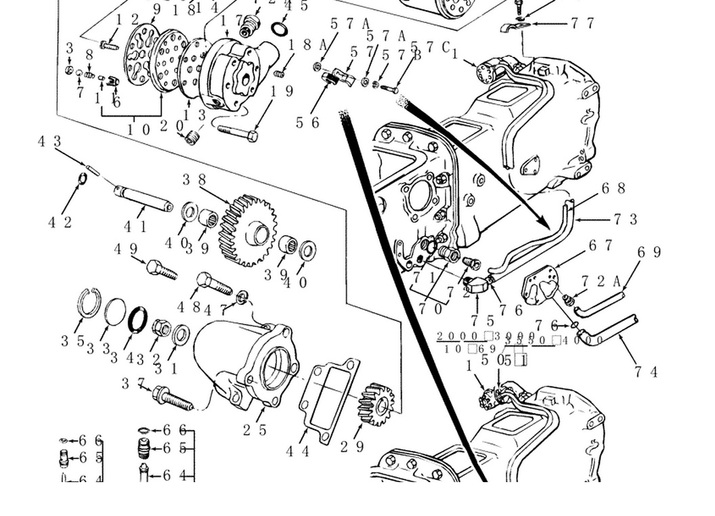

I have used the forums on this site to do several repairs to my recently purchased Ford 3400 tractor. Thank you everyone who have posted to the site, your comments are more helpful than you will ever know. I am currently rebuilding the hydraulic piston pump on the tractor and I am stumped as to how I remove the round metal plug on the rear of the gear housing in order to access the nut holding the pump shaft in place. The instructions in the IT manual say to remove the snap ring on the outside and then remove the plug. I got the snap ring off just fine but the directions do not describe how to remove the plug. I do not want to cause any damage by banging on it without knowing exactly how it comes out. I need to pull the pump shaft out in order to replace the seal and the bearings but I cannot get to that nut without pulling the plug out first. I've stared at this pump for hours and researched it until I was blue in the face. Attached is a picture of the parts diagram for this pump. Part number 33 is the plug I am trying to remove. Any help would be appreciated. Thank you,

Aaron

<image src="http://forums.yesterdaystractors.com/photos/mvphoto18183.jpg"/>

Aaron

<image src="http://forums.yesterdaystractors.com/photos/mvphoto18183.jpg"/>