I am nearing the end of a project and would like to share some pictures as a primer for a new part that should soon be available for the Minneapolis Moline pullers.

I've been working with several people on port and chamber development, a pattern maker, foundry, etc. These heads have much improved porting, combustion chambers and are designed to look and fit as originals but perform much better. They have water jackets also.

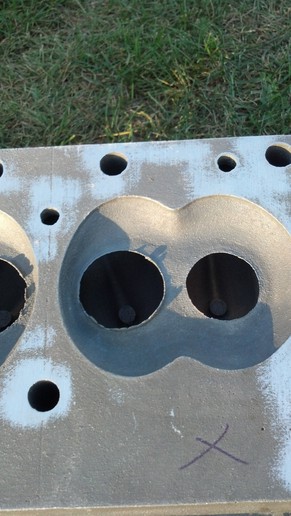

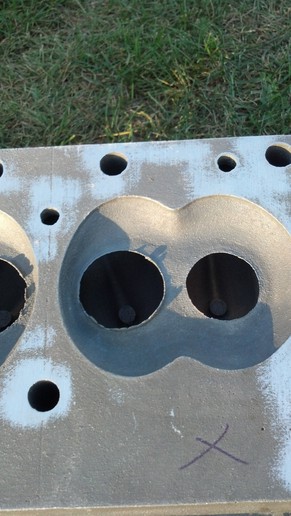

Here's a picture of the new head and an old original. Bear in mind that these pictures are of raw castings. Currently I'm in the machining process of turning the castings into pieces ready to accept valve train.

I've been working with several people on port and chamber development, a pattern maker, foundry, etc. These heads have much improved porting, combustion chambers and are designed to look and fit as originals but perform much better. They have water jackets also.

Here's a picture of the new head and an old original. Bear in mind that these pictures are of raw castings. Currently I'm in the machining process of turning the castings into pieces ready to accept valve train.