Mike(NEOhio)

Well-known Member

- Location

- Newbury, Ohio

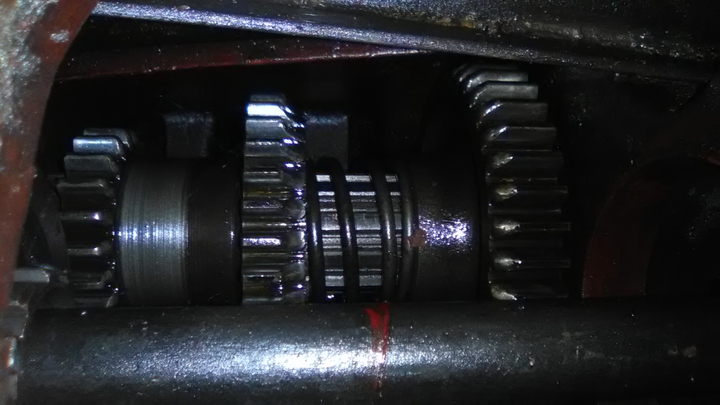

I put the engine back on the E4 today and cannot get it to slide all the way back to the mounting holes. The clutch and PTO splines are engaged but it needs to go back another 7/8 inch. I put a new bronze bushing in it and checked so it fit good on the input shaft. I had the input shaft and sleeve off to clean and check. The input shaft and sleeve had wear at the front end just behind the splines as if the shaft was off-center to the sleeve. With the splines engaged I could feel gap between the shaft and sleeve was tight at the bottom. Thought it may have been the clutch disk off center so I turned the flywheel 180 and it's still the same. The parts manual show shims at the front engine mount but not at the back. Looks as if the engine is sitting too low in the tub.