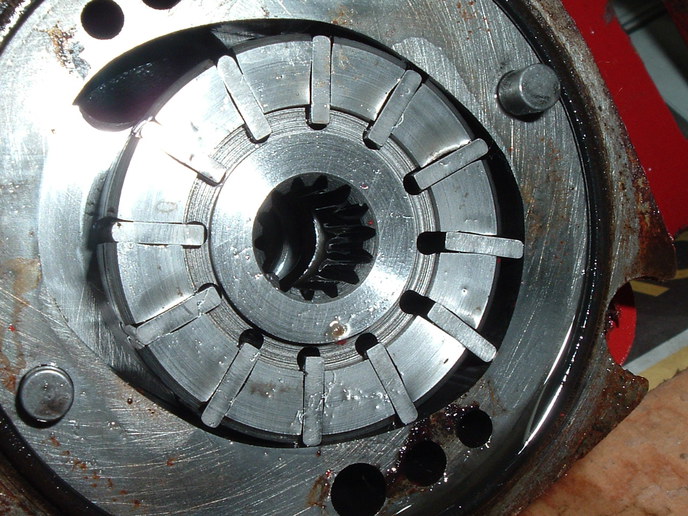

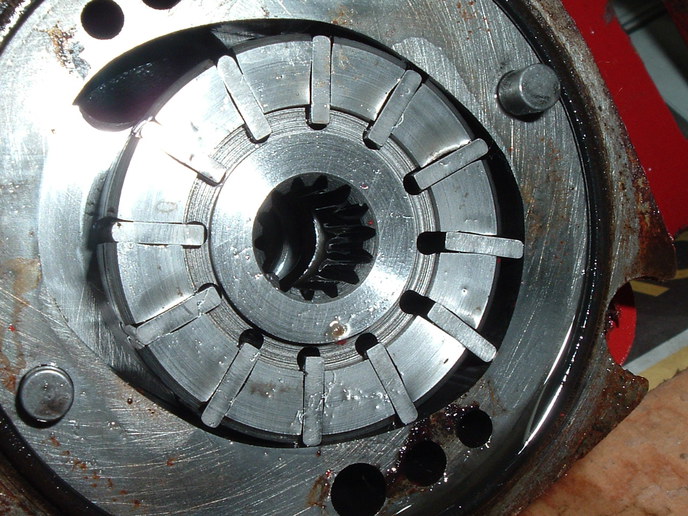

The attached pic is from the power steering pump on my Cockshutt 540. It is Vickers. I took the pic as I dis-assembled the pump to replace the seal on the front shaft. That has been done.

However, the way the vanes sit in the rotor does not look right to me. The rotor has rounded edges on the inside, whereas the vanes have the rounded edges to the outside against the ring. I am thinking someone before me put this together wrong.

Your opinions?

I am restoring this tractor. I bought it not running. This summer I got it running and drove it up and down my driveway a few times. The power steering seemed to work okay, except for the leak.

However, the way the vanes sit in the rotor does not look right to me. The rotor has rounded edges on the inside, whereas the vanes have the rounded edges to the outside against the ring. I am thinking someone before me put this together wrong.

Your opinions?

I am restoring this tractor. I bought it not running. This summer I got it running and drove it up and down my driveway a few times. The power steering seemed to work okay, except for the leak.