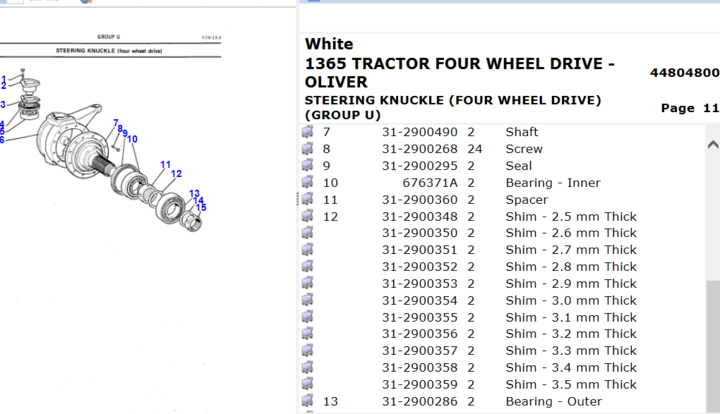

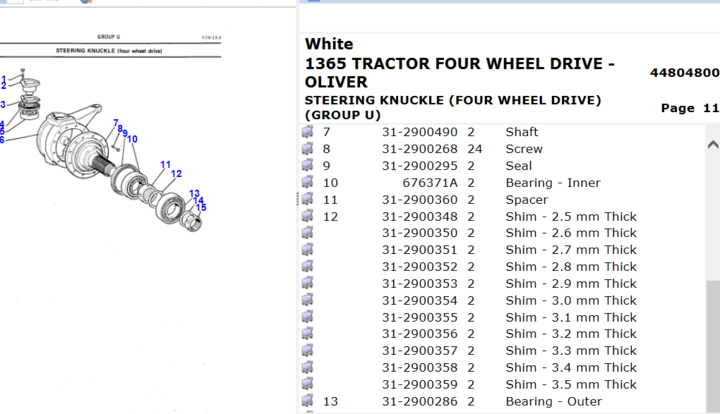

That number 12 shim. I didn't see it until I had already cut it in half with the torch. It goes between the number 11 spacer and number 13 bearing. Number 10 and 13 are both just tapered wheel bearings shown with the outside race. I don't know how you'd ever know what the right thickness was with new bearings unless you used something like Plasti-gauge to measure it. The one I cut in half measured 3.0mm. You'd think with that in there is would cause slop eventually when those bearings wore in a little?

I went ahead and put it together and tightened it up until is rolled OK with no shuck at all in the wheel or hub. I'm wondering if I should call and order one or just leave it like it is?

There's nothing to stop a wheel bearing in a normal hub,like a two wheel drive or wagon or something is there? You just tighten it up and put the cotter pin in the castle nut.

These bearings roll in 90wt oil in the planetary.

I went ahead and put it together and tightened it up until is rolled OK with no shuck at all in the wheel or hub. I'm wondering if I should call and order one or just leave it like it is?

There's nothing to stop a wheel bearing in a normal hub,like a two wheel drive or wagon or something is there? You just tighten it up and put the cotter pin in the castle nut.

These bearings roll in 90wt oil in the planetary.