Is anybody familiar with the power steering on the 1365 Cockshutt/Oliver?

Mine's FWA,no secret there. From time to time it steers OK,other times not. If I put down pressure on the loader and lift the front,I can spin it right around with one finger in the middle of the steering wheel. The reservoir is full,I took the filter screen out and cleaned that.

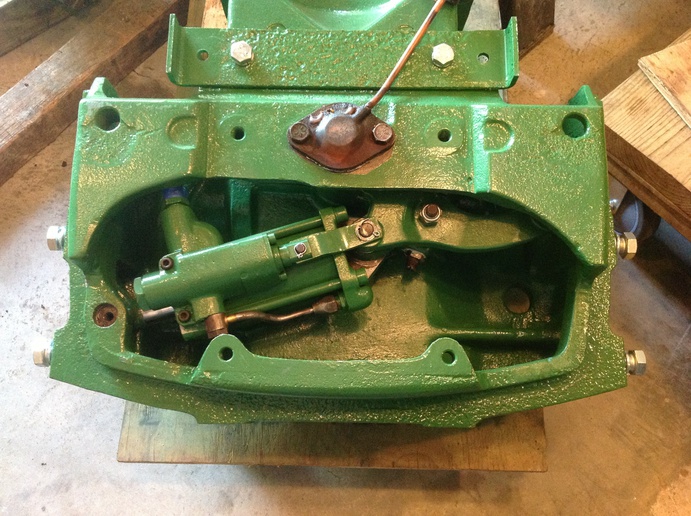

It seems like if it turns one way going forward,say to the left,it won't turn the other direction. When I start to back up,then it will turn the other way. Am I right in thinking that there is a cylinder up under the battery or somewhere that activates when the drag link starts to move? If that's the case,is there an adjustment somewhere? It's like there must be some movement in the front axle forward and back when the tractor changes direction that lets is activate going one way,then the other way when I go the other way.

Am I right in that assumption?

The loader is in the way of getting in there,getting the battery out and doing something about it,but if I knew I was going to get it fixed by taking the loader off so I could get to it,I'd do it.

Mine's FWA,no secret there. From time to time it steers OK,other times not. If I put down pressure on the loader and lift the front,I can spin it right around with one finger in the middle of the steering wheel. The reservoir is full,I took the filter screen out and cleaned that.

It seems like if it turns one way going forward,say to the left,it won't turn the other direction. When I start to back up,then it will turn the other way. Am I right in thinking that there is a cylinder up under the battery or somewhere that activates when the drag link starts to move? If that's the case,is there an adjustment somewhere? It's like there must be some movement in the front axle forward and back when the tractor changes direction that lets is activate going one way,then the other way when I go the other way.

Am I right in that assumption?

The loader is in the way of getting in there,getting the battery out and doing something about it,but if I knew I was going to get it fixed by taking the loader off so I could get to it,I'd do it.