Dennisinponca

Member

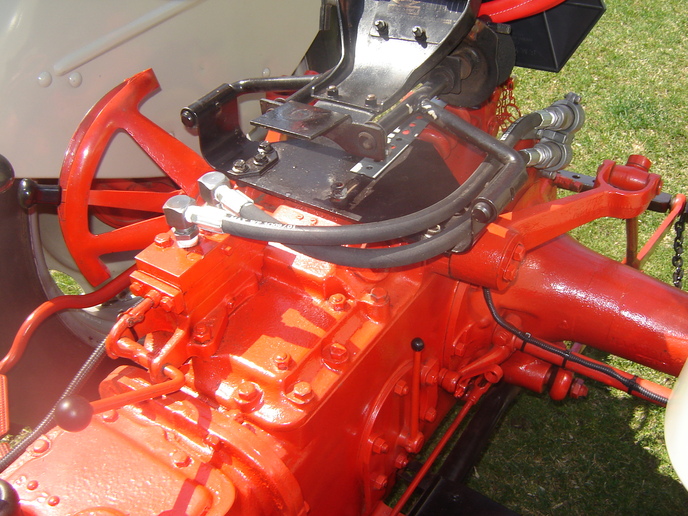

Here is a picture of the dual hydraulics remote on my Jubilee. I removed the seat to show the item better. These are fairly rare on the 53 / 54. The Ford Aux. plate changed in 55 so the newer remotes do not fit the NAA or earlier series.

As you can see, it sits just above and forward of the draft control, it replaces the aux. cover.

As you can see, it sits just above and forward of the draft control, it replaces the aux. cover.