TheOldHokie

Well-known Member

- Location

- Myersville, MD

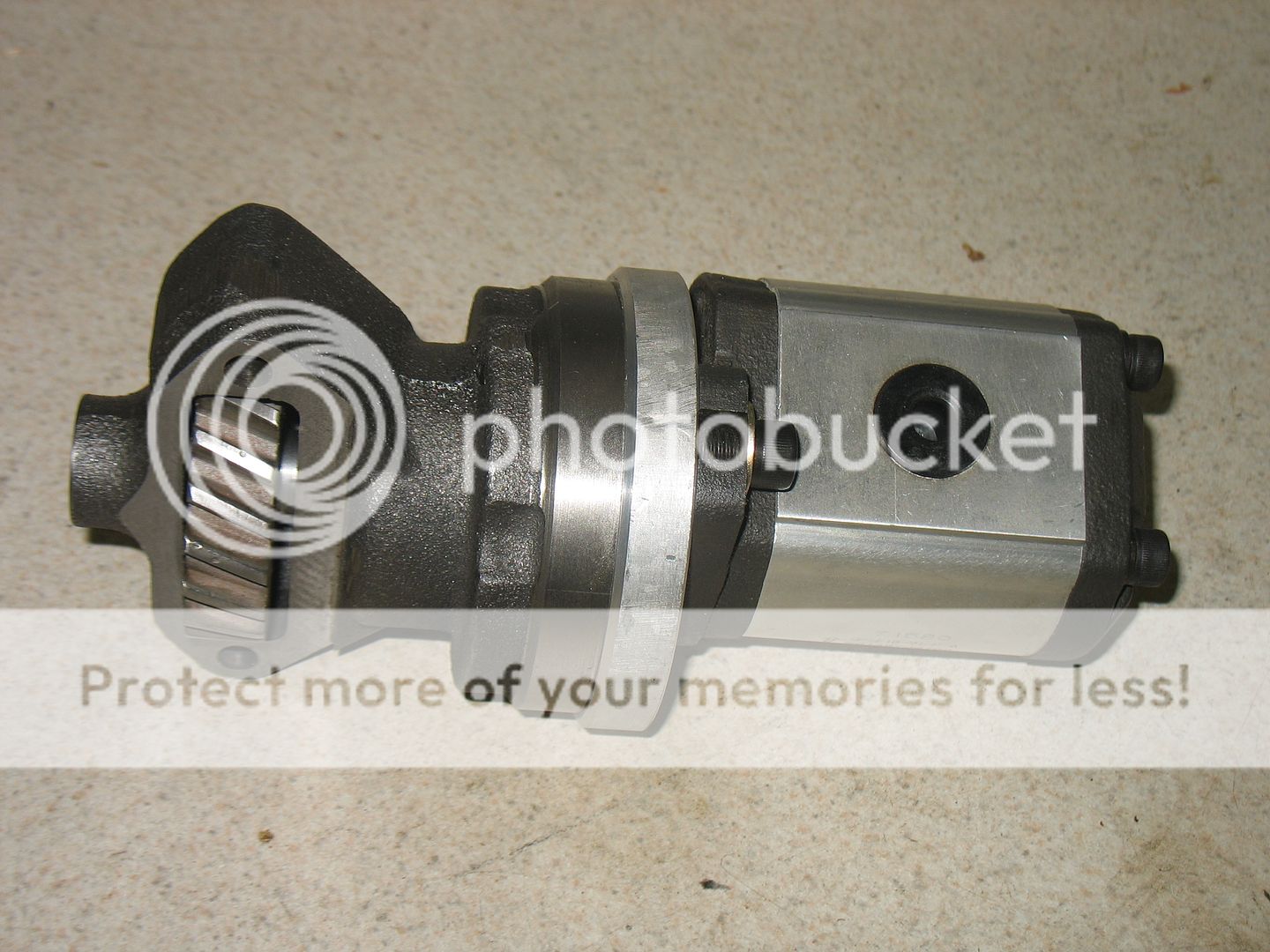

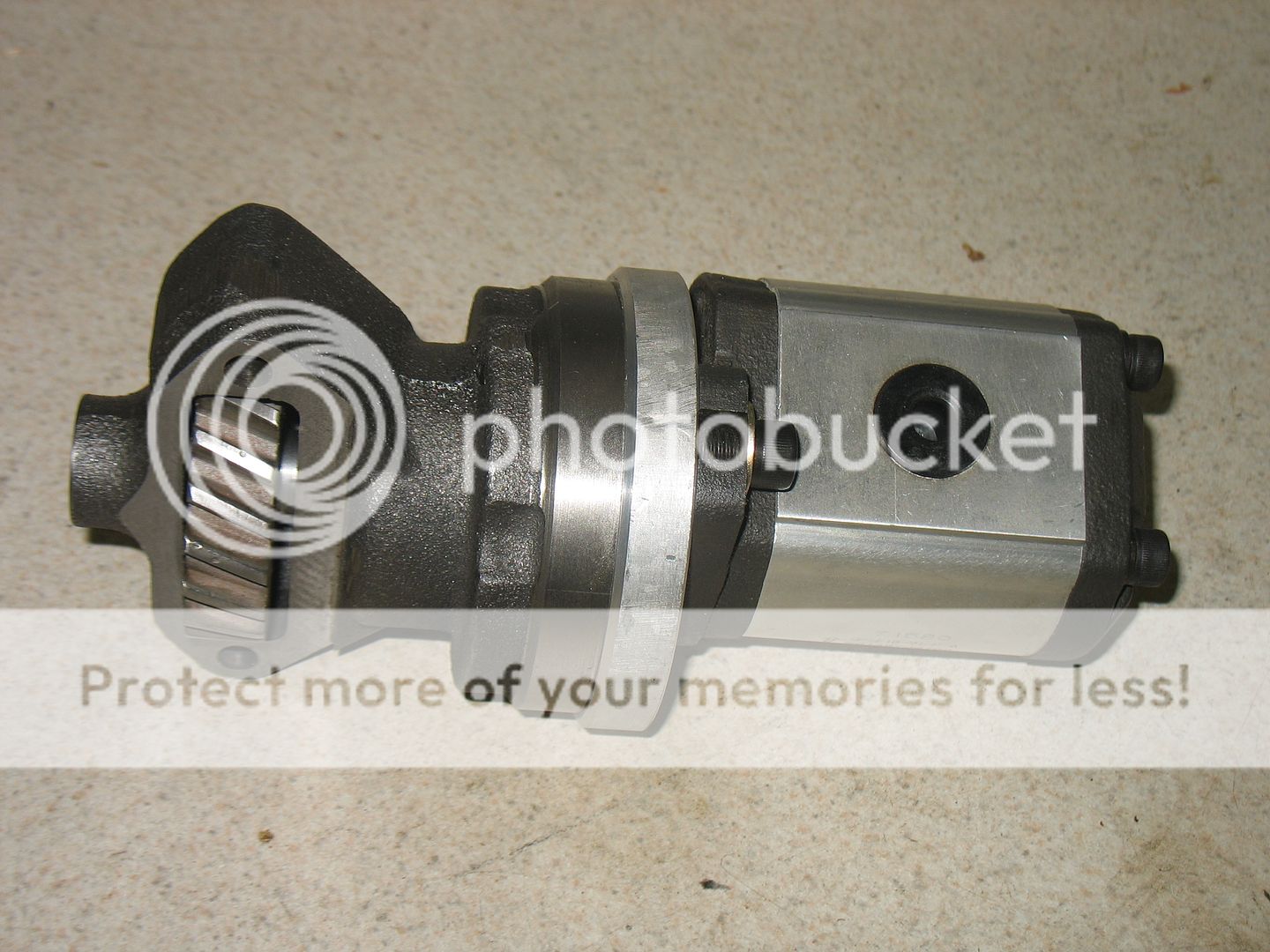

My gear pump retrofit for the vane pumps has been quite popular but making them fast enough to keep up with demand has been a real problem. I decided there had to be an easier way and this is what just came out of the engineering department ;-)

It uses the NCA-905C gear housing that was used on the piston pumps. Unlike the vane pump housings I can get them new on the aftermarket AND they already have provision for a needle bearing and a tapered roller bearing to support the wobble shaft in the piston pump. It's an easy modification to machine the pump mounting ears off and rebore the oil seal seat for a double row radial ball bearing. A new easy to make intermediate shaft that runs in the OEM needle bearing and new radial bearing replaces the wobble shaft, oil seal, and tapered roller bearing and a simple adapter to marry the gear pump to the end of the housing completes the retrofit. I also think it looks a lot more "professional" than the blocky adapter I was using. This one is going to a customer who has been waiting a very long time. He will verify the fit and function for me but I don't expect any problems and expect to have these conversions available in the near future. They will be complete direct bolt on replacements for either the piston or vane pump. Simply remove the old pump, cut the hydraulic lines off, bolt on the new pump and reconnect the lines with the hoses and fittings provided. Hopefully I will be able to do a better job of keeping pace with demand.....

TOH

It uses the NCA-905C gear housing that was used on the piston pumps. Unlike the vane pump housings I can get them new on the aftermarket AND they already have provision for a needle bearing and a tapered roller bearing to support the wobble shaft in the piston pump. It's an easy modification to machine the pump mounting ears off and rebore the oil seal seat for a double row radial ball bearing. A new easy to make intermediate shaft that runs in the OEM needle bearing and new radial bearing replaces the wobble shaft, oil seal, and tapered roller bearing and a simple adapter to marry the gear pump to the end of the housing completes the retrofit. I also think it looks a lot more "professional" than the blocky adapter I was using. This one is going to a customer who has been waiting a very long time. He will verify the fit and function for me but I don't expect any problems and expect to have these conversions available in the near future. They will be complete direct bolt on replacements for either the piston or vane pump. Simply remove the old pump, cut the hydraulic lines off, bolt on the new pump and reconnect the lines with the hoses and fittings provided. Hopefully I will be able to do a better job of keeping pace with demand.....

TOH