Do you recall the scene in the movie "Cool Hand Luke" when the warden says to Luke "What we have here is failure to communicate."?

You've got a bunch of folks trying to help you but all we're getting is no response or one word cryptic nonsensical replies.

You're making a simple problem a lot more complex by your lack of communication.

So lets start over. I'll outline all the steps you need to take.

If you do not understand something, say so.

If you are asked a question, either answer it or please say you do not understand the question.

The first thing you need to check is bushing wear. If the shaft has any sideways movement AT ALL, the bushings must be replaced. (see below)

Next, look at how the points & condenser are set in the distributor before you start pulling it down! Turn the tang & observe how the points open & close. If this is your first time doing it, draw a sketch! Make sure you are using quality points. I use only Wells, Blue Streak or Echlin brand points (* see below). Be careful not to ground the tip of the condenser wire to the body of the distributor when you replace the points. Do not break the little copper strip that go to the points. (If you do, make another out of the old set of points). Also, make sure the condenser wire does not go through the same opening in the distributor as the coil pig tail. The condenser wire goes through the opening on the top right.

Look at the old points; are they burned, pitted or misaligned? Check the point gap, .015 on all four lobes. Make sure the blade is at a perfect right angle to the points. You want to feel just the slightest bit of drag when you pull the blade through the points. Set the points on the high side of the cam and ensure they align correctly. Make sure you have the star washers under the screws on the points. If you need to replace the 8-32 X .19 fillister head screws, ensure that the new screws do not interfere with the advance weights. Dress the points by running a piece of card stock or a brown paper bag through them. New points sometimes have an anti-corrosive dielectric coating on them & old points can corrode or pick up grease from a dirty feeler gauge or excessive cam lubricant. And, don?t forget to lube the rubbing block w/ cam lube; not Vaseline, not bearing grease, but cam lube (** see below).

If you are using quality points and cannot get the gap to open to .015, chances are you need to replace the bushings.

Now, set the timing. Get a meter or test light, a 21/64? drill bit (*** see below) & a metal straight edge. Put the distributor face down w/ the condenser on the left & the timing plate lock screw on the bottom. Look at the end of the shaft: it has a narrow side & a wide side. Make sure you can tell the difference. Now, place the drill bit in the bottom mounting hole (this will be your reference point for measuring). Next, place a straight edge on the wide side of the tang on the shaft as shown in fig. FO83 in the picture. Rotate the shaft CCW (as viewed from rotor side OR CW as viewed from back/tang side) until the straight edge is ?" beyond the outside edge of the drill bit you stuck in the distributor mounting hole. At this distance, the distributor points should start to open (get your meter/light out now & check). If not, loosen the timing plate lock screw and turn to advance or retard the timing (move the plate down to advance timing, up to retard). Remember, each one of those little hash marks represents about 4? of timing. Keep adjusting until you get the proper ?" setting. (if the plate won?t move, you might need to remove the big C clip to loosen it a bit) As you?re adjusting, eliminate backlash by turning the shaft backwards (CW as viewed from the front) and bring the shaft forward (CCW as viewed from the front) to measure your setting. This ?" setting will get you static timing at top dead center.

After you set the points & timing, do a continuity check before you put the distributor back on the tractor. Before you start, make sure your meter/light works.

With the distributor still off the tractor, follow these steps:

1. Coil off, cap off, points open. One probe on the brass screw & the other on both sides of the open points. On the side closest to the cam, you should have continuity. Not on the other side! If you do, you will also have continuity everywhere because the points are grounded.

2. Coil off, cap off, points open. One probe on the brass screw & the other anywhere on the body of the distributor. You should have no continuity! Now, rotate the tang on the distributor....as the points open & close, you have continuity (closed) and lose it when they open.

3. Put the coil on the distributor, cap off, points open. One probe on the lead on the top of the coil, the other on the cam side of the open points. You should have continuity!

4. Coil on, cap off, points open. One probe on the lead on the top of the coil, the other anywhere on the body of the distributor. You should have no continuity!

Assuming that the bushings & advance weights are ok, & that you have correct voltage to the coil (battery voltage with the points open and about half that with the points closed), the most common electrical failure (no spark, weak spark) points on the front mount are:

1. The insulator under the brass concave head screw & where the copper strip attaches. (it?s fiber & will wear out; poke & prod w/ your meter leads to make sure it still works) If you need to replace the insulator, use a .250 x 3/8 nylon square nylon anchor nut available at most big box home stores

2. The pigtail at the bottom of the coil not making contact w/ the concave head brass screw inside the distributor. (With the coil on, the pigtail must firmly contact the brass screw. No contact = no spark

3. The copper strip is broken or grounded to the plate. (look very carefully for cracks & breaks).

4. The condenser wire grounding to the plate or side of the distributor.

5. The tab on the bottom of the coil not making contact w/ the brass button on the cap. (With the cap on, the tab must firmly contact the brass button. No contact = no spark.)

6. Incorrect positioning of the spring clip on the plate causing the pigtail to ground. (the open part of the clip goes between 7 & 9 o?clock on the plate. That puts the straight part of the clip opposite of the timing screw at 3 o?clock)

7. Incorrect seating of the coil on the distributor due to a loose bail or no gasket.(the coil must not move at all; if it does, replace the gasket or bail. Or stick some cardboard under the bail).

8. Water/moisture inside the cap due to gasket failure or the absence of a gasket. (the cap AND coil have gaskets)

9. Dirty/corroded/burned/incorrectly gapped or misaligned points. I use only Wells, Blue Streak or Echlin brand points (* *see below). If you are using quality points and cannot get the gap to open to .015, chances are you need to replace the bushings. If the shaft has any sideways movement AT ALL, the bushings must be replaced.

10. Burned rotor, cracked/carbon tracked cap.

At this point, I just put the distributor, coil & cap all back on the tractor as a unit. The reason I do this is because it is real easy to get the cap or coil misaligned trying to put it back together, one piece at a time. The result is something gets broken or you get a ?no spark? problem.

It's possible to put it back on wrong & break it. Look at the slot on the end of the cam shaft. Whatever angle it happens to be, turn the distributor tang to match it. Make sure you can tell the wide side from the narrow side on both the cam & distributor! (close counts). Place the distributor on the front of the engine, gently push it in place & slowly turn the distributor body until you feel the tang slip into the slot. Rotate the distributor body until the bolt holes line up. Hand tighten the two bolts until the distributor body is flush with the timing gear cover.

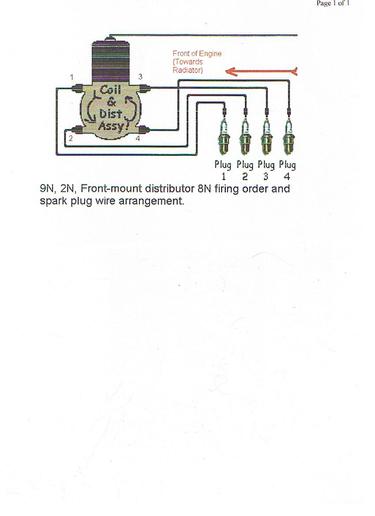

Double-check your firing order & plug wires. It?s 1-2-4-3, counterclockwise. It?s very easy to cross 3 & 4.

And finally, do not forget to remove the distributor on an annual basis (more often, depending on use) to check the point gap and re-lube the cam.

* NAPA part numbers:

? Points: FD-6769X

? Condenser: FD-71

? Rotor: FD-104

? Cap: FD-126

** Distributor cam lube:

http://www.napaonline.com/Catalog/Result.aspx?Ntt=ECH+ML1&Ntk=Keyword&Nty=1&Dn=0&D=ECH+ML1&Dk=1&Dp=3&N=0

** Distributor cam lube

http://www.carquest.com/webapp/wcs/stores/servlet/subcategory__10151_-1_10651_11340

*** Rather than the drill bit, a jig made by Dan Allen (The Old Hokie) will make this task quicker & more accurate.

http://windyridgefarm.us/

**** Unscrew the plate hold down screw & remove the C clip to get the plate out. Remove the shaft & weights. The weights should freely move.

There are three ways to replace the bushings in a front distributor:

1. Buy new bushings (part numbers 9N12120 front & 18-12132 rear). Press out the old ones, press in the new ones and ream to fit. CAUTION: do not try this unless you have a press & know how to use it. If you break the base, a new one costs $130. If you bend the tower which holds the front bushing, a new plate will cost you $30.

2. Take the new bushings and distributor to your local machine shop.

3. Send the distributor out for bushing replacement if you do not have a local machine shop.

Make sure your distributor isn?t worn out; check the wear parts with a micrometer and compare what you have to the factory specs (below).

Factory Specs:

Shaft top .4367 / .4370

Shaft Bottom .8625 / .8630

Cam Flats .789 / .791

Cam Lobes .869 / .871

Base Tang .177 / .178

75 Tips any :idea:

any :idea: