RedBarnNate

Member

Hello!

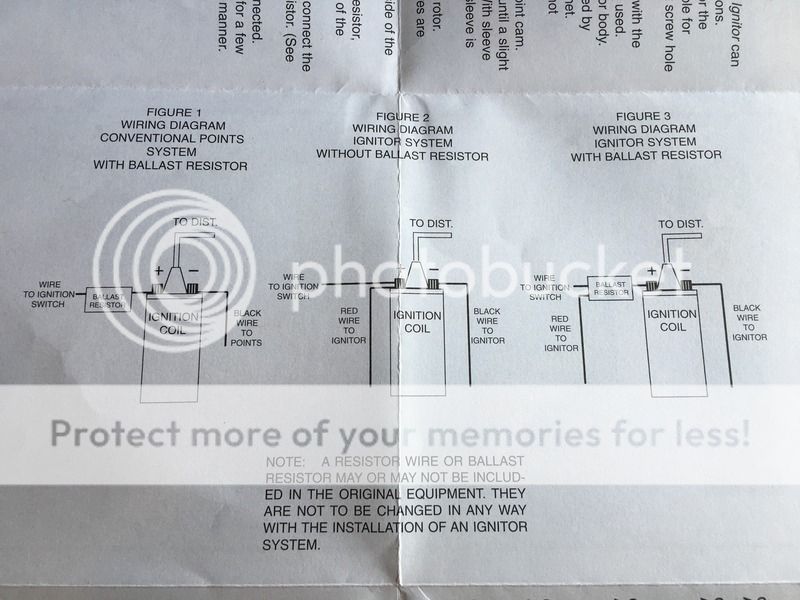

I'm not sure if this is in the right section, but I want to convert my dad's Ford 950 Row Crop tractor to 12 volt. Here are some current pictures of the tractor charging components.

1. I want to do this job RIGHT.

2. I want to do this job SAFELY.

3. I want to get a complete list of correct parts to use and a diagram before ordering ANYTHING.

Can someone be of assistance? Willing to learn.

I'm not sure if this is in the right section, but I want to convert my dad's Ford 950 Row Crop tractor to 12 volt. Here are some current pictures of the tractor charging components.

1. I want to do this job RIGHT.

2. I want to do this job SAFELY.

3. I want to get a complete list of correct parts to use and a diagram before ordering ANYTHING.

Can someone be of assistance? Willing to learn.