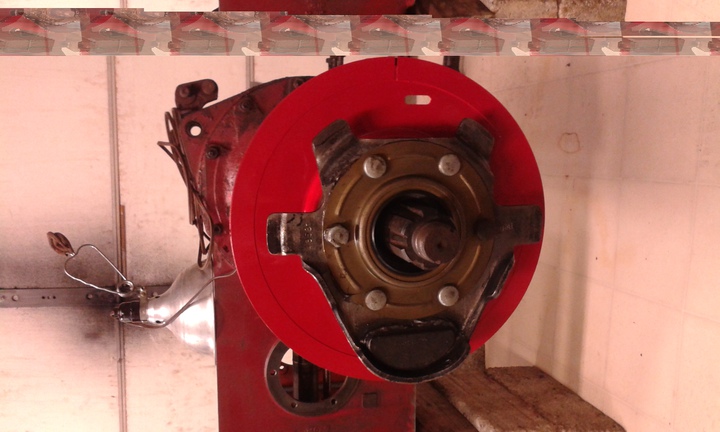

Ok guys got a question just to make sure I did everything ok. I put 3 on each side to start with expecting it to be too tight and it was. I was actually turning the the transmission. The manual says that the opposite axle should be rotating the same direction when too tight. In this case the opposite side was not turning at all.

So I added another shim to each side. This time it was much easier to turn the axle on one side and the opposite side was turning opposite direction.

For the heck of it I removed one shim on one side only and I had a slight drag and the axles were turning opposite of each other. so I put the other shim back in. There is no side shaft play at all so I think I'm good,but my question is why arn't my axle shafts turning in the same direction when too tight like the manual says and what I've read online? Could something else be wrong?

So I added another shim to each side. This time it was much easier to turn the axle on one side and the opposite side was turning opposite direction.

For the heck of it I removed one shim on one side only and I had a slight drag and the axles were turning opposite of each other. so I put the other shim back in. There is no side shaft play at all so I think I'm good,but my question is why arn't my axle shafts turning in the same direction when too tight like the manual says and what I've read online? Could something else be wrong?