" By the way, how do you tell an 8N from a 9N?"

A 9 or 2N will have a 3 speed transmission.

But......

It could still have an 8N engine.

Check out this site: http://www.oldfordtractors.com/idhistory.htm

If you're going to own a 65+ year old tractor, you really need the manuals. Even a toaster comes w/ a manual.

See tip # 39 at the link.

Assuming your tractor is a 9/2N:

First, put your battery on a charger. (see tip # 60)

You need a strong battery to:

1. Spin the starter

2. Spin the bendix

3. Provide voltage to the coil.

As the battery gets weaker, the first thing to fail is your spark.

In addition to charging the battery, chances are you may need new cables as well (tip # 41). And, don't forget to clean all the grounds, to include the mating area between the starter & the block.

The more current you use to spin the starter, the less you have for the ignition.

Next, replace the plugs. If you flooded it, they're fouled & it will be it next to impossible to start. You don't need to toss them; heat the tips for a few seconds w/ a propane torch to burn off the invisible spark-robbing deposits from today's additive filled gasoline........or wash them in lacquer thinner.

It takes three things for an engine to run: spark at the right time, compression, & fuel/air in the right mixture. For the moment, forget about compression & concentrate on narrowing the problem down to spark or fuel.

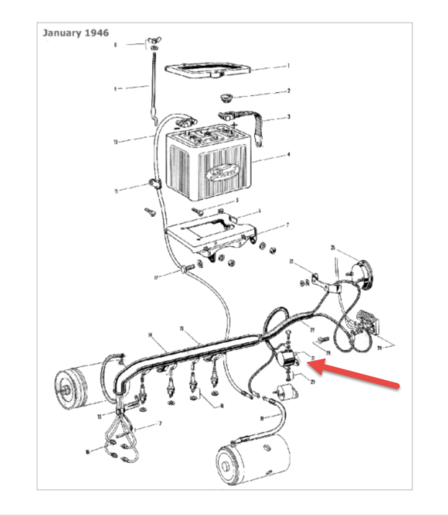

There are three very important tools you always need to have in your N tool box: a 3 inch piece of wire w/ alligator clips on each end, a spark checker w/ an adjustable gap (* see below) and a 7/16 box end wrench. (see tip # 50 at the link below) And, you really do need a working ammeter on the tractor; it is a very important diagnostic tool. With these tools, you can quickly narrow down most N problems to spark or fuel.

First, turn the key on, crank the engine & look at the ammeter. What is the needle doing? Does it show a constant discharge, no movement at all, or does it move back & forth slightly? Next, hook up your spark checker, turn the key on & crank the engine. If the spark jumps the 1/4” gap, you probably don’t have a spark problem. If it won’t jump the ¼” gap, you have a spark problem. If the ammeter needle shows a constant discharge, or doesn’t move at all, that also tells you that you have a spark problem. Jump the ignition switch w/ your jumper wire & see what happens. If it runs, you found the problem. If it doesn’t have spark after you jump the ignition switch, post back for more info on further troubleshooting. (and do not forget to turn the ignition switch off; see tip # 38

Next, check for fuel. Get a can & put it under the carb. Remove the bolt in the bottom of the carb; as long as the fuel is turned on, you should see gas flowing out of the carb. Let it run for at least 30 seconds. If it’s a dribble, or runs for 5 seconds & stops, or none at all, you have solved half the problem: it’s fuel related. If gas flows well out of the carb & only stops when you turn it off at the sediment bowl, chances are very good it’s not a fuel problem.If it does not have gas coming out of the carb at a steady stream w/ the bolt out for at least 30 seconds, you have a fuel problem. First, remove the gas cap. Your vent could be clogged & it vacuum locked. If that doesn’t work, tap the carb bowl w/ a hammer handle in case the float is sticking closed. (don’t whack it w/ the head of the hammer; you can crack the bowl). If you still don’t see gas flowing, the N has three fuel screens; one in the brass elbow, one in the top of the sediment bowl & one on the stem of the sediment bowl in the gas tank. Check the screen in the elbow & the screen in the top of the sediment bowl. (don’t worry about the one in the tank) Both probably need to be cleaned. If you have the fuel knob turned on all the way, & 1 gallon or less in the tank, it may be trying to feed off of the reserve inlet which is probably clogged. Only open it 2 full turns. Put at least 2 gallons in the tank. (and do not forget to turn the gas off; see tip # 9)

There are ways to check for spark & fuel that work & ways that don't. For example, having gas to the carb is nice, but having it past the float is what counts! That’s why removing the 7/16” bolt in the bottom of the carb is the way to check for fuel. And, same thing w/ spark at the plugs. Some folks think that checking for spark means pulling a plug wire off & looking for one. Well, it's the distance the spark jumps at the plug that gives you the info you want. It takes about 17kv to jump a 3/16" gap & 22kv to jump ¼” in the open air. Remember, it’s 14psi outside of the engine & about 90psi at a 6:1 compression ratio in the cylinders & compressed air creates electrical resistance, so you really need the 17-22kv to fire the plugs when the engine is running. A store bought plug checker (in the picture) will work better than an old plug because it won’t shock the snot out of you like an old plug might!

Post back with results or more questions.

*If you don’t own a spark checker w/ an adjustable gap, buy one. In the meantime, an old spark plug w/ the gap opened to at least ¼” will work. Ground it to a rust & paint free spot on the engine turn the key on & look for a spark.

75 Tips