flembo

Well-known Member

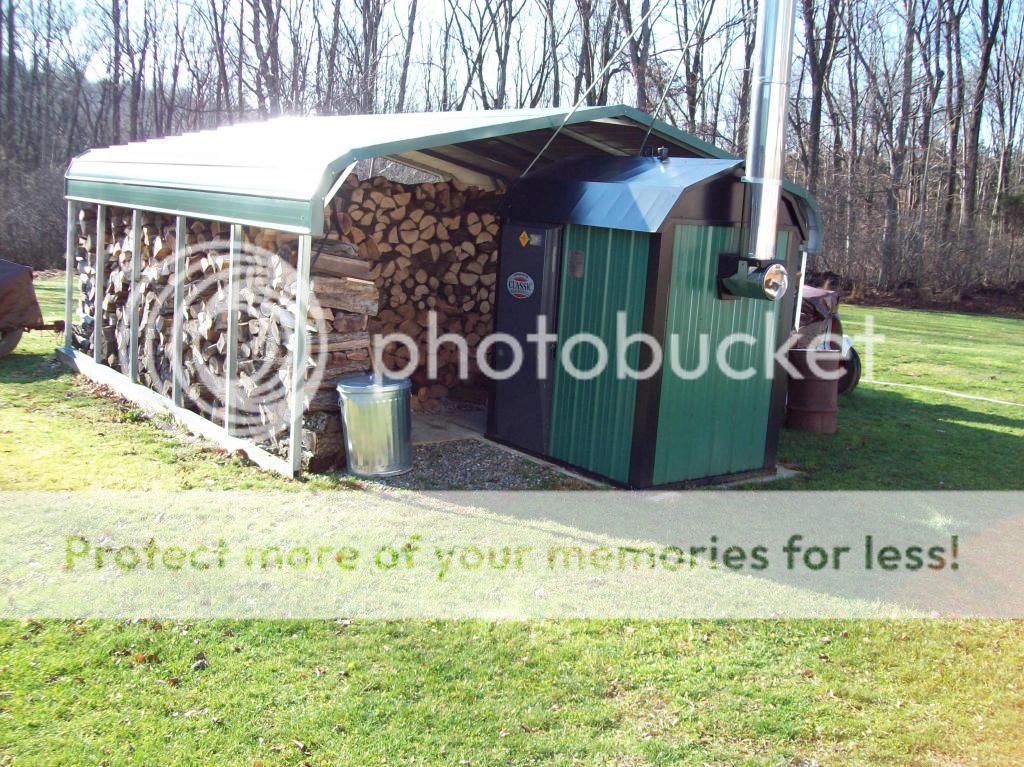

The shed is full for this yr. and the 2015 2016 season is cut split and piled, a few more trailer loads will insure that. What's left in the log pile will cover the 2016 2017 season. The best part is the size of the logs a lot of them won't need to be split some will need to be split in half and a few 12" or 13" stuff to quarter but no backbreakers like shown on the splitter typical of last yr. My back will like that, it's a nice feeling knowing that the wood is in. I do have 2 big birch trees that are dead or dying I will take down this winter when the ground is hard.