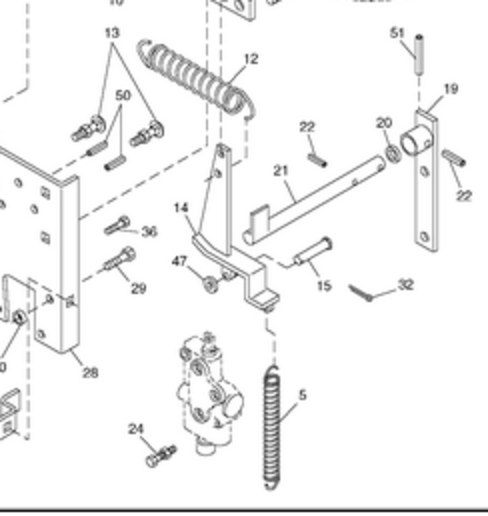

I disassembled the bucket cylinders on my Paulson loader.Rod with seals on it was extremely hard to get out of the cylinder. Had to put a bar in the eye of the rod and hammer to remove the piston with seals. Multiple type of chevron seals, o rings.

The nut at the end of the rod: Had to use a 3/4 inch flex bar, 1.5 inch 3/4 socket and a piece of pipe on the end or flex bar. Secured the rod by putting a crowbar through the eye end ofrod and putting my tractor on one end of the crowbar. Nuts were pin punched to prevent them from coming loose. Wanted to know, Is it really necessary to have the nuts this tight? What about tightening and use locktite. I think the cylinders have been together since they were put on the loader.

The nut at the end of the rod: Had to use a 3/4 inch flex bar, 1.5 inch 3/4 socket and a piece of pipe on the end or flex bar. Secured the rod by putting a crowbar through the eye end ofrod and putting my tractor on one end of the crowbar. Nuts were pin punched to prevent them from coming loose. Wanted to know, Is it really necessary to have the nuts this tight? What about tightening and use locktite. I think the cylinders have been together since they were put on the loader.