kylemorley

Member

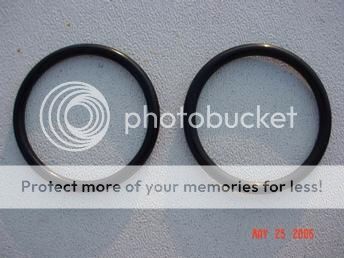

Any good guidelines on when to condemn a lift cylinder? I pulled mine today, and found the bore in lovely shape - but for one lone scratch running the length of the bore, measuring about .008" across and maybe .005" deep after I cleaned up a bit with a cheap drill hone.

I hate to spend money on new parts when old will do but I am not experienced enough with these things to know how much leakage that will translate into.

I hate to spend money on new parts when old will do but I am not experienced enough with these things to know how much leakage that will translate into.