Colin King

Well-known Member

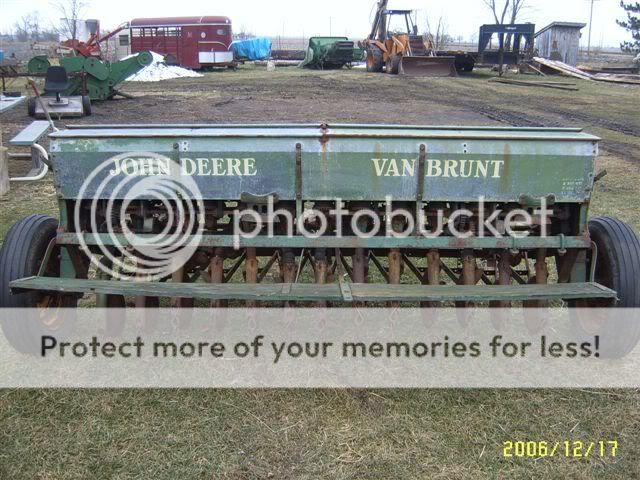

An old friend of the family's sold me his very well maintained Van Brunt 10' grain drill this week.

The drill was on the east side of town, so I brought the truck home with me from the farm yesterday before supper with the idea that I would pull it home and then today take it the remaining 10 miles to the farm.

I got back into town with the drill behind the truck right around 5:30 last night. I'm a block away from home at the second busiest intersection in town (intersection of busy state and federal highways) when the right wheel of the drill freezes up. I stop - I'm blocking the south bound lane of the federal hwy and the turn lane as well as any eastbound access from the state hwy. I can't tell what happened, but the chain guard is all mangled up.

I have to get out of the road, so I put the truck in low and pull as hard as that little Ranger can, with the locked wheel squealing, about 50 feet to the street where my house is. I pull over, walk home, get tools, jacks, blocks, and tell my wife that instead of being on-time for supper, I'll late.

Turns out that the counter shaft sprocket completely disintegrated. When it did so, it jammed up the drive chain which crushed the chain guard and locked the right wheel. Sprocket is in 7 pieces. There are a number of lengthwise cracks in the sprocket sleeve that slips over the square counter shaft. Looking at the other shaft, this looks like the primary wear point.

Thankfully the machine appears to work with no other damage other than a broken chain, chain guard, and sprocket. I got the drill to the farm this afternoon. I'll have to order the sprocket from JD, which runs 97 bucks! The 8N better like this drill

Colin, MN

The drill was on the east side of town, so I brought the truck home with me from the farm yesterday before supper with the idea that I would pull it home and then today take it the remaining 10 miles to the farm.

I got back into town with the drill behind the truck right around 5:30 last night. I'm a block away from home at the second busiest intersection in town (intersection of busy state and federal highways) when the right wheel of the drill freezes up. I stop - I'm blocking the south bound lane of the federal hwy and the turn lane as well as any eastbound access from the state hwy. I can't tell what happened, but the chain guard is all mangled up.

I have to get out of the road, so I put the truck in low and pull as hard as that little Ranger can, with the locked wheel squealing, about 50 feet to the street where my house is. I pull over, walk home, get tools, jacks, blocks, and tell my wife that instead of being on-time for supper, I'll late.

Turns out that the counter shaft sprocket completely disintegrated. When it did so, it jammed up the drive chain which crushed the chain guard and locked the right wheel. Sprocket is in 7 pieces. There are a number of lengthwise cracks in the sprocket sleeve that slips over the square counter shaft. Looking at the other shaft, this looks like the primary wear point.

Thankfully the machine appears to work with no other damage other than a broken chain, chain guard, and sprocket. I got the drill to the farm this afternoon. I'll have to order the sprocket from JD, which runs 97 bucks! The 8N better like this drill

Colin, MN