greywolf224

Member

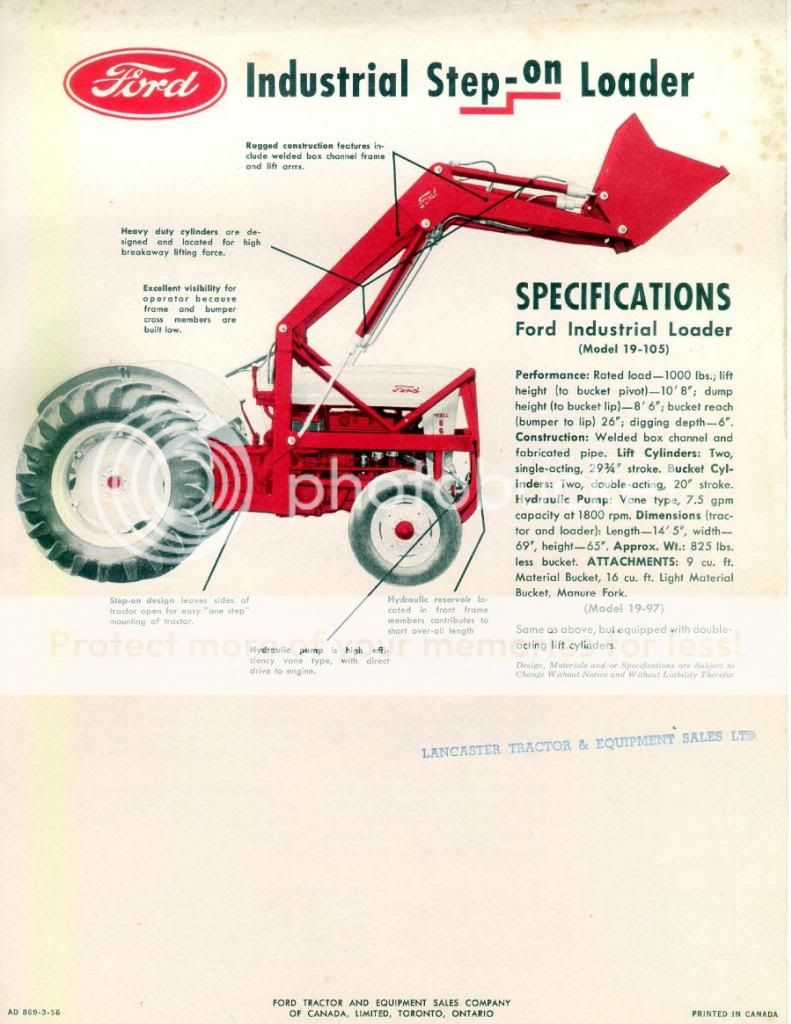

Does anyone know the info behind my Vickers vane pump that I have on my Dear born 19-70 front end loader.(See picts) Specifically gpm flow and PSI. It doesn't leak at all and powers the loader perfectly. But I want to know what I am working with so I know what I need to build.

Since I removed the loader (for now)I want to use it to create a live PTO using the test port and also setting up some remote rear ports to power a few other things.

My idea is to remount the pump (Thanks to the Old Hokie who is fixing my pump bracket) on the front shaft and supply a flow divider so that I can control the flow to the test port down to approx 2.5 gpm and then supply a dual spool valve config under the seat to supply a couple of remote ports.

I don't want to use the current hydraulic system fluid rather mount a remote 5 gallon tank somewhere????? ANY IDEAS

The Old Hokie doesn't know it yet but I will be tapping into him for ideas and parts that i hope he can supply me with.

Since I removed the loader (for now)I want to use it to create a live PTO using the test port and also setting up some remote rear ports to power a few other things.

My idea is to remount the pump (Thanks to the Old Hokie who is fixing my pump bracket) on the front shaft and supply a flow divider so that I can control the flow to the test port down to approx 2.5 gpm and then supply a dual spool valve config under the seat to supply a couple of remote ports.

I don't want to use the current hydraulic system fluid rather mount a remote 5 gallon tank somewhere????? ANY IDEAS

The Old Hokie doesn't know it yet but I will be tapping into him for ideas and parts that i hope he can supply me with.