You should upgrade or use an alternative browser.

- Thread starter Mister B

- Start date

I am 80 on all cylinders, so I did not do a wet test as they seem evenly worn.

I had not thought of the blow by idea -smart- is there a way to measure that, either with instrument or ?

Ultradog MN

Well-known Member

- Location

- Twin Cities

Mention low compression and or low oil pressure and the fellows here are gonna talk you straight into a $2000 engine rebuild - complete with crank grind, line bore, deck the block and mill the head.

I never understood that way of thinking since when you finish you'll have a tractor worth about $2500.

I say you are on the right track and can do a lot for a tired engine with a ring ridge ream, rings, rod bearings and a head and pan gasket. That'll get you on down the road for 10 more years or untill you discover an N isn't quite enough tractor and you move on to a lil bigger one.

TheOldHokie

Well-known Member

- Location

- Myersville, MD

(quoted from post at 14:43:08 04/07/13) Have a 1940 9n with 80 PSI compression all around. Weighing simply a ring job with replacement bearings on crank.

Question is: will this alone fix oil pressure? Or is there more to replace to bring pressure back up?

No. You are talking two different issues:

1) You have low compression - that is rings/pistons/valves and/ory a valve job.

2) You have low oil pressure which indicates excessive bearing and/or oil pump clearances.

If you need rings (and that seems likely) a complete kit with new rings, pistons, and sleeves is my recommendation. Do the valves while you are there.

If you need bearings (seems likely) you likely need rods and mains and a regrind on the crankshaft. And rebuild the oil pump while you are in there.

At that point it becomes a complete overhaul.

JMO,

TOH

You do know the N-Engine was designed fer 30-wt detergent oil, don't you??? 15-40wt oil is really just 15wt oil with heat sensitive additives that make it act like 40wt oil. CHANGE yer engine oil to 30wt detergent and watch yer oil pressure climb.

How do you detect "blow-by"??? Oil fumes out yer oil fill'em-up cap. ........Sheesh; respectfully the amazed Dell

TheOldHokie

Well-known Member

- Location

- Myersville, MD

(quoted from post at 18:12:48 04/07/13)

You do know the N-Engine was designed fer 30-wt detergent oil, don't you??? 15-40wt oil is really just 15wt oil with heat sensitive additives that make it act like 40wt oil. CHANGE yer engine oil to 30wt detergent and watch yer oil pressure climb.

........Sheesh; respectfully the amazed Dell

Utter nonsense. If there is any observable change (doubtful) you will see a small drop in hot oil pressure with a grade 30 oil. Additives or not SAE 15W40 has a higher viscosity than straight SAE 30 when hot, And that is what affects hot oil pressure - PERIOD!!!!

TOH

Weighing simply a ring job with replacement bearings on crank.

..... is there more to replace to bring pressure back up?

A lot has to do with time , money , and how much you need a tractor .

If your time is free and you enjoy doing your own mechanic work then you can refresh the motor with some rings and bearings .

A used N is not really the tractor you want if you are paying some one else to rebuild the motor , etc .

To bring the pressure up I would spend a few bucks getting the oil pump rebuilt . These oil pumps sit above the oil line and have to suck oil up before it builds pressure . Worn pumps can easily lose prime which causes the motor to run dry on start up .

You wont really know about reringing until you get it apart . The thin steel sleeves can end up in the oil pan when they are excessively worn , the cast thick sleeves stay intact .

Again money has a lot to do with it , fresh bearings will take out a lot of slack . For about $125 - $150 you can get it in fair shape . If you are reringing a used cylinder , I would not use the chrome rings since they are harder to get to seat in . A plain steel ring won't last as long , but since the cylinder is already worn there is no real loss .

Before you take out the valves , see if they will hold a spoon full of gasoline from leaking past . If they will then lap them and go .

Utter nonsense. If there is any observable change (doubtful) you will see a small drop in hot oil pressure with a grade 30 oil. Additives or not SAE 15W40 has a higher viscosity than straight SAE 30 when hot, And that is what affects hot oil pressure - PERIOD!!!!

TOH

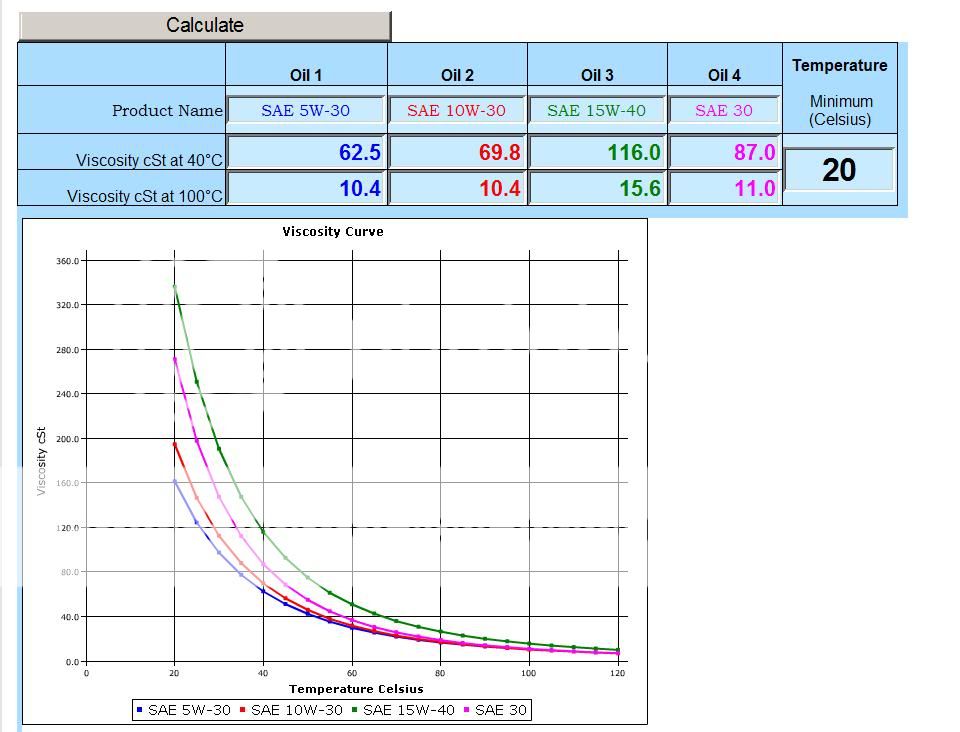

Whats up with the cold viscosity of the 15w40 ? Those numbers look like straight 40 ??

Shouldn't the cold (15w) be somewhere between the 5w/10w and the straight 30 ?

62.5 - 69.8 - [color=red:239d11d442]116.0[/color:239d11d442] - 87.0

I will change the oil pressure guage first (anybody recommend one with a low pressure range? The one I have goes way too high anyway.). If that doesn"t work, oil pump rebuild.

I had done ATF in the spark holes already. I think I"ve got genuine 80# PSI all around. Will do a wet test and check for blow by. I will cogitate on the need for rings/bearings after all that.

Thanks Fellas - I really appreciate it! Mister B.

TheOldHokie

Well-known Member

- Location

- Myersville, MD

(quoted from post at 22:09:12 04/07/13)

Whats up with the cold viscosity of the 15w40 ? Those numbers look like straight 40 ??

Shouldn't the cold (15w) be somewhere between the 5w/10w and the straight 30 ?

62.5 - 69.8 - [color=red:d03a74d4ac]116.0[/color:d03a74d4ac] - 87.0

No because the 40C measurements are not how the the SAE cold weather gradesare assigned. The cold weather grades are determined by viscosity measurements at much colder temperatures (-20C to -35C). The 40C/100C measurements are the input values for the industry standard method of computing full engine oil viscosity curves (ASTM D130). That graph is produced by feeding actual product data for Valvoline All-Fleet engine oil into an online ASTM D130 caclulator program provided by Robert Widman (Widman Oil)..

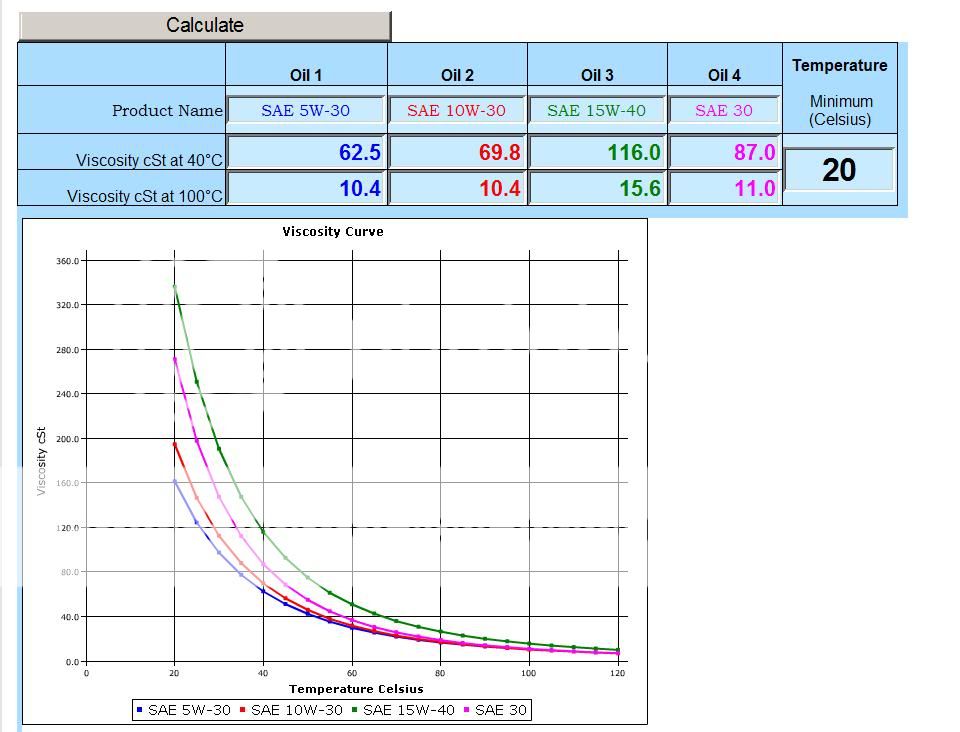

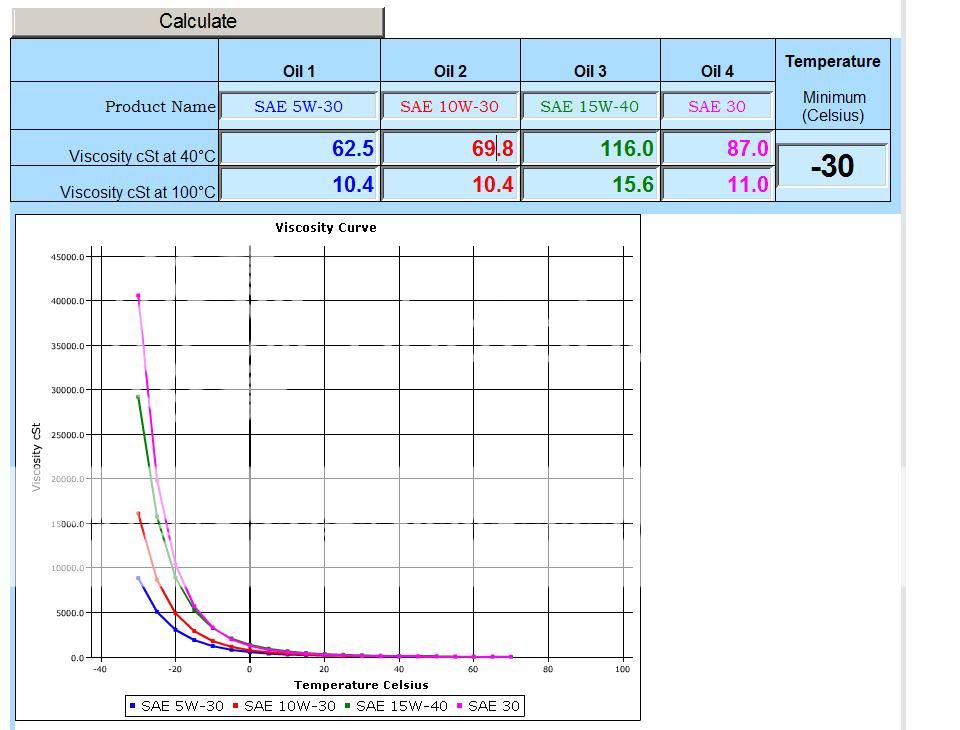

Because oil viscosity changes exponentially with temperature a non-logarithmic graph can't visually separate the curves over the entire temperature band very well and I only provided the upper end on the graph so you could clearly see the separation up there. Here is the sub-zero portion of the same curves rescaled so you can see the differences at that end. The surprising thing for most people is that SAE 15W40 is only a marginally better cold weather performer than a monograde SAE 30 and doesn't drop under the SAE 30 viscosity curve until around -10C. At or near freezing the SAE 30 is actually thinner.

TOH

Because oil viscosity changes exponentially with temperature a non-logarithmic graph can't visually separate the curves over the entire temperature band very well and I only provided the upper end on the graph so you could clearly see the separation up there.

OK , Thanks for the info .

So a 2000 rpm rated flat head engine needs only 20 psig minimum oil pressure at the gauge when operating at normal operating temperature.

30 psig is better.

That is the reason for the low range oil pressure gauge.

The 9N9273A replacment oil pressure gauge

is 0-50 psig. The 20 & 30 numbers on the dial are actually larger than the 10 & 40 psig numbers.

The 0 & 50 numbers are smaller then the 10 & 40 numbers.

Understand the reason to go from SAE 30wt to SAE 15-40 wt or SAE 15-40wt to SAE 20-50wt is to compensate for worn crankshaft bearings.

TheOldHokie

Well-known Member

- Location

- Myersville, MD

(quoted from post at 10:19:21 04/08/13) Always thought that the engine needs minimum 10 psi oil pressure for every 1000 rpm.

Couple thoughts for you to mull over:

- [*:c0c34561f4]What if any engineering basis is there for that "rule of thumb"?[*:c0c34561f4] How does an old flat head B&S lawn mower engine run happily along year after year at 3600 RPM with absolutely zero "oil pressure"?[/list

:c0c34561f4]TOH

TheOldHokie

Well-known Member

- Location

- Myersville, MD

(quoted from post at 04:09:43 04/09/13) and genrators and irrigation pump engines at zero oil pressure with light weight crankshafts and two & four cycle outboard engines and motor cycle engines.

gravity:

its the gravity load on the crankshaft.

What keeps the journal off the bearing surface in a small engine that does not have an oil pump (e.g "zero" engine oil pressure) is the same thing that produces the oil film in an engine with an oil pump. Journal bearings operate on the principle of hydrodynamic lubrication. The oil film that separates the journal surface from the bearing surface is produced by the rotation of the journal dragging the oil inside the bearing clearances around the circumference and constricting it at the narrower load point. That constriction produces a localized pressure gradient inside the bearing that is orders of magnitude greater than oil pump pressure and is opposed to the operating load (and gravity) imposed on the journal. The basic parameters affecting the film thickness are crankshaft load, rotational surface speed of the journal, oil viscosity, and running oil clearance.

You can externally pressurize a normal journal bearing but if the crankshaft is not rotating it remains on the surface of the bearing. It simply sinks to the bottom of the evenly pressurized oil clearance area. When the engine is started and journal rotational speed begins to increase a hydrodynamic pressure gradient is formed at the load point and that pressure gradient acts to push the journal surface away from the bearing surface. The journal/bearing lubrication regime transitions from full boundary mode lubrication (metal to metal) when the rotational speed is zero, to a mixed mode (partial metal to meatl contact) as the speed begins to increase and the film is partially formed, and ideally to full hydrodynamic mode (zero metal to metal contact) when the rotational speed becomes sufficient to produce a gradient greater than the load on the journal. Teh film thickness is determiend by how much the gradient exceeds the load on the journal. Oil pump pressure is not involved beyond maintaining an oil supply adequate to replenish oil lost out the sides of the journal during operation. Small engines traditionally relied on splash lubrication for that oil supply.

TOH

Ok, so why does the flatheat N have the 0-50 psig oil pressure gauge and the OHV NAA have the 0-80 psig oil pressure gauge?

Both engines have equal rated 2000 rpm and nearly equal 6.6/6.7 CR after 85000 serial #.

The oil pump capacity was increased at some point on the N series?

Larger capacity oil pump would increase the back pressure at the journal at equal RPM?

Maybe the larger capcity pump was incorporated to increase the longevity of the engine and not to increase the oil pressure on a new or new rebuilt engine?

So what is the concern about oil back pressure, since the oil pressure is not in the equation for oil film thickness?

In my opinion the N series engine needs to have minimum of 15 psig oil pressure @ 1500 rpm.

Maybe the NAA needs more oil back pressure than the N, since the gauge has a greater range or with a larger capacity pump than the N, the oil pressure is higher.

The tire mfg's are always researching & testing to come up with the ultimate thread pattern to reduce the chance of hydroplaning, which creates a thin film of water between the tire and road in heavy rain conditions. The water film supports the "gravity" weight of the vehicle, which is basically the same physics as the engine journal. Michelin Tire has a great video on U-Tube.

Oil pressure issue seems to be one of the most frequent FAQs on the N forums.

AKA "raven" on the NTC forum

An SAE 10-30 wt oil is base 10 wt with viscosity index (VI) improver (heat sensitive additives)

The VI improver additives are susceptable to shearing damage in non synthetic oil. The damage can occur very early in the life of the oil, reducing the effective weight of the oil from 10W-30 to 10W-20.

Ever notice that when the oil is changed when using non synthetic multiple weight oil, the oil pressure gauge shows an increase in pressure? After the oil is used for a while, the oil pressure gauge shows a reduction in the oil pressure because the VI improvers have been damaged by internal engine shearing action.

Using synthetic muti weight oil the shear damage issue is basically eliminated.

Still, Prefer using straight SAE 30 non synthetic and change it once a year in my N whether it is used or not.

TheOldHokie

Well-known Member

- Location

- Myersville, MD

[color=red:17f80b4a38]Always understood that most of the journal wear occurs at start up rather than at normal operating conditions.

[/color:17f80b4a38]

That is normally the case since that is the transition from boundary to hydrostatic regime. Luging an engine alsl contributes to accelerated wear since increased load at lower RPM equates to a reduced oil film thickness and mixed mode lubrication.

[color=red:17f80b4a38]Ok, so why does the flatheat N have the 0-50 psig oil pressure gauge and the OHV NAA have the 0-80 psig oil pressure gauge?[/color:17f80b4a38]

WAG - the engineers wanted a higher pumping pressure and increased flow rate to accomodate the greater demands of the OHV design. A flathead doesn't need top end lubrication but an OHV does and it needs it nearly immediately on startup. The oil pressure gauge on my 1963 Triumph equipped with a similar size and vintage Standard engine is 100 PSI and the Leyland specification is a minimum idle hot oil pressure of 30 PSI hot. With an OHV you have to move more oil, move it further, and get it there faster. An OHC is even more demanding in that regard.

[color=red:17f80b4a38]So what is the concern about oil back pressure, since the oil pressure is not in the equation for oil film thickness?[/color:17f80b4a38]

It is a easily collected performance metric. The issues I just mentioned are part of that performance but pump oil pressure is also a very good indirect measure of bearing clearances. Bearing clearances ARE a factor in oil film thickness and a low pumping pressure indicates increased clearances and a reduction/loss of the protective oil film.

[color=red:17f80b4a38]In my opinion the N series engine needs to have minimum of 15 psig oil pressure @ 1500 rpm.[/color:17f80b4a38]

A fresh engine with good oil clearances will easily make 40 PSI at 1500 RPM. I would say that an engine with 15 PSI @ 1500 RPM is telling you it has wide clearances and/or a worn oil pump and is nearing the end of it's service life. It's those widened clearances that will cause accelerated engine wear - not the low oil pressure.

TOH

TheOldHokie

Well-known Member

- Location

- Myersville, MD

(quoted from post at 12:46:16 04/09/13) Multi weight engine oil has viscosity index improvers that reduce the thinning with increase in operating temperature.

An SAE 10-30 wt oil is base 10 wt with viscosity index (VI) improver (heat sensitive additives)

The VI improver additives are susceptable to shearing damage in non synthetic oil. The damage can occur very early in the life of the oil, reducing the effective weight of the oil from 10W-30 to 10W-20.

Ever notice that when the oil is changed when using non synthetic multiple weight oil, the oil pressure gauge shows an increase in pressure? After the oil is used for a while, the oil pressure gauge shows a reduction in the oil pressure because the VI improvers have been damaged by internal engine shearing action.

Using synthetic muti weight oil the shear damage issue is basically eliminated.

Still, Prefer using straight SAE 30 non synthetic and change it once a year in my N whether it is used or not.

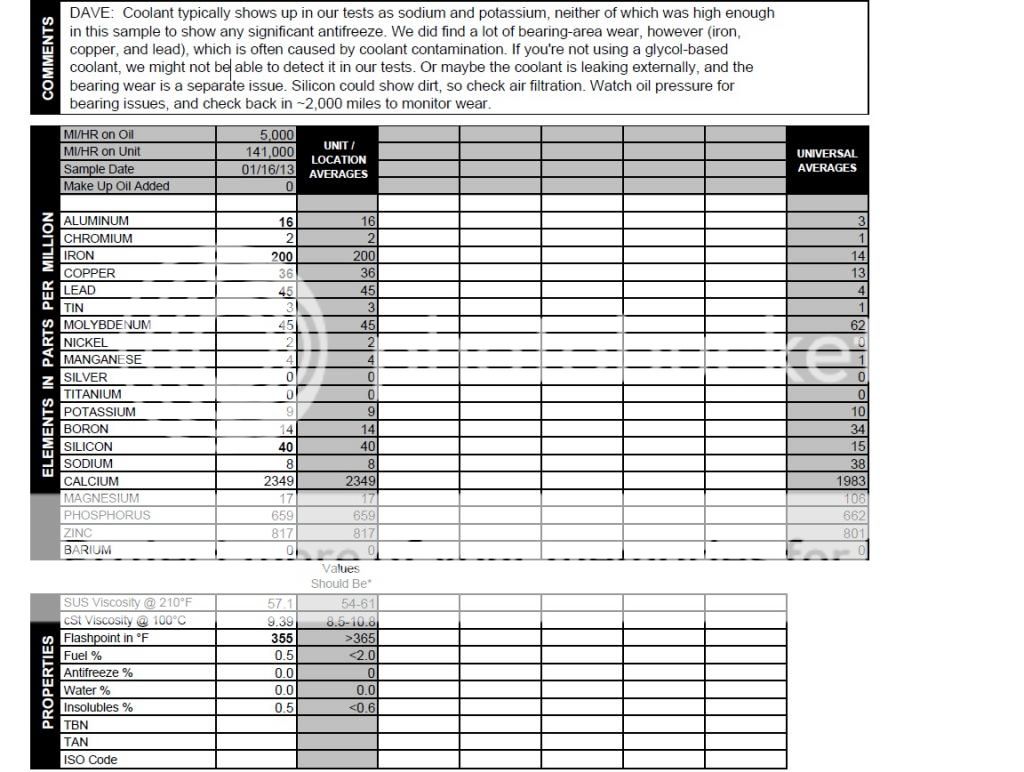

[b:b047a10d2b]All[/b:b047a10d2b] oil shears down. I don't know where you get your empirical data but I prefer laboratory analysis to anecdotal observation. Excessive shear loss on a [b:b047a10d2b][u:b047a10d2b]quality[/u:b047a10d2b][/b:b047a10d2b] conventional multi-grade oil is darn near non-existent. A used oil analysis is a good way to see this and there are many consumer testing services that will provide you with one. Just send them a small used oil sample and for ~$20 they will give you an analysis similar to this one. This UOA is a typical result showing the performance of a modern semi-synthetic/conventional 5W30 and as you can see the oil is still well withing viscosity grade after 5K miles and could probably go another 5K if you wanted to push it. The typical failure mode of a modern oil is over-thickening due to oxidation not viscosity shear down There are hundreds of similar UOA's available for viewing on the BobIsTheOilGuy website and you will find this level of perfortmance is typical of conventional oils with synthetics doing much better.

Conventional SAE 10W30 can (and occasionally is) formulated using a very high viscosity index (VHVI) conventional base oil and no viscosity modifiers whatsoever. SAE 10W30 synthetics are commonly formulated without viscosity modifiers. So this idea that the W grade is the "real" viscosity is factually inaccurate and only serves to confuse/scare people. Buy a good oil and change it on a normal interval and you won't have a problem with shear down.

TOH

PS> I added a second UOA for a conventional SAE 5W30 - still going strong but just barely out of grade after 9.2K miles - nearly double the recommended OCI for a conventional oil. Note the lab says he could stretch the OCI to 11K ....

My thought is leave the journals alone unless the bearings are being eaten up and throwing lots of metal into the oil.

It is easy to replace the main bearings and rod bearing on this engine while the engine is bolted up to the transmission and front end.

Bearings are cheap compared to a rebuildable crankshaft, which are becoming more difficult to locate.

So if the oil pressure < 15 psig at 1500 rpm at normal operating temperature, then change out the bearings. Grind journals only if there is noticable bearing metal material mixed in the oil. This will help preserve the N tractor for generations to come.

Hobo,NC

Well-known Member

- Location

- Sanford, NC

(quoted from post at 05:28:00 04/14/13) The Blue ribbon goes to LB!!! Changed the new oil gauge with another. Amazing how that brought up the oil pressure (Ha Ha!). Will need a ring/bearing job soon enough. Have line on a 9n engine parted out. I think I will use the tractor while I rebuild that, then do the swap out. Too much fun.

Mite satisfy you but not me,,, how do you know the other reads correct... :?:

Similar threads

- Replies

- 5

- Views

- 411

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy