Years ago had oil in radiator of an 8N. Took tractor to mechanic who repaired - said cause was a blown head gasket.

Have a '50 8N with oil in radiator and low compression on cyls 2 & 3. Decided to tinker myself.

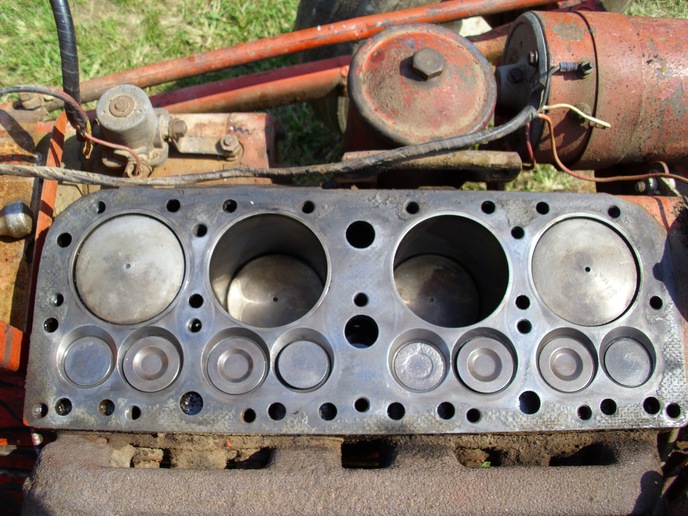

Photo (I hope) shows gasket still on head. Bits left on block. I don't see anything "blown".

What am I missing?

If gasket wasn't "blown", then what are other possibilities for oil in water?

Thanks.

Have a '50 8N with oil in radiator and low compression on cyls 2 & 3. Decided to tinker myself.

Photo (I hope) shows gasket still on head. Bits left on block. I don't see anything "blown".

What am I missing?

If gasket wasn't "blown", then what are other possibilities for oil in water?

Thanks.