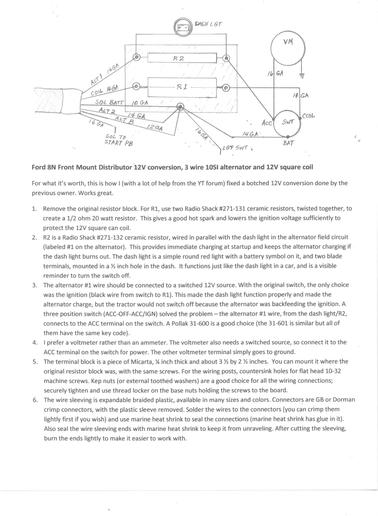

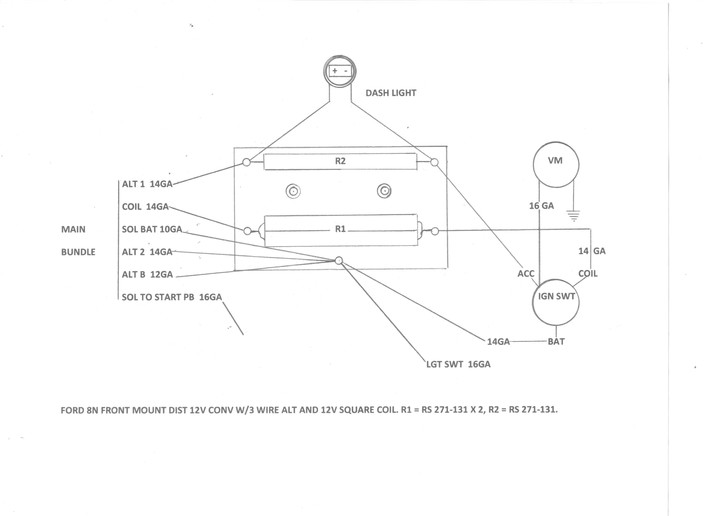

Thanks for all I have learned reading this forum. I bought a 48 8N last year and have worked through several issues (thermostat was upside down, distributor cam weight came off, fiber cam gear broke, had low oil pressure, governor was worn out, wiring was bad, wrong carburetor was installed, etc) to finally get it running pretty good. Couldn't have done it without your help. I was really sorry to hear that Dell passed away; he was very helpful to me. The best thing I learned from him was the double resistor (Radio Shack 271-131) trick for a 12V conversion on a front mount distributor 8N. It provides a good hot spark and protects the 12V square coil. The other resistor in the photo is in the alternator field circuit, along with a dash light. I'm told it provides immediate charging at startup and makes the alternator keep charging even if the dash light burns out. Everything is mounted on a 1/4 inch thick Micarta board. This setup seems to work great. The tractor starts instantly and the plugs run clean. I also used a 3 position ignition switch (Pollak 31-600) to provide another switched 12V source and prevent feedback to the ignition circuit when the tractor is switched off (it would keep running with the original switch).

This forum is great! Thanks again for all the great advice.

This forum is great! Thanks again for all the great advice.