Anonymous-0

Well-known Member

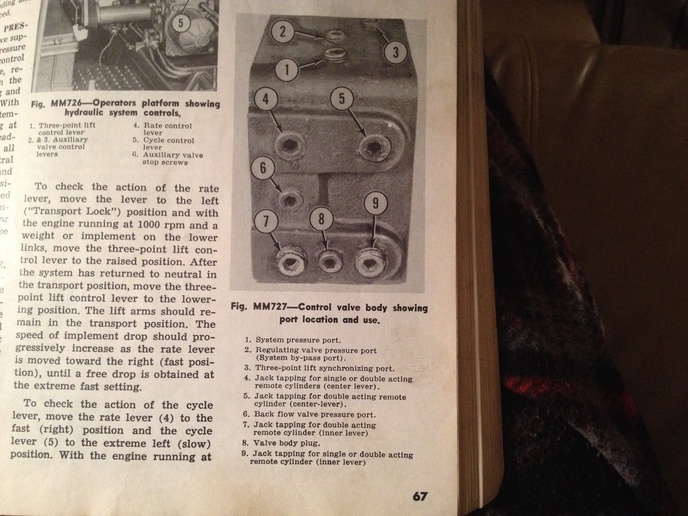

Based upon responses to my last post, and checking the service manual I replaced the hydro hoses that were leaking. I couldn't try to lift the plow again because its 3 miles away, and it was in the low 20's in Ohio today (didn't feel like freezing on the first day of the new year)! So I hooked up to my Bush Hog 6' finish mower and lifted it with no problem. I then added 6 suitcase weights to the rear of the mower (figure it would be close to 1000 pounds). It only lifted it 3/4 of the way up. I consulted with JoePro, and decided to increase the spring tension on the relief valve. I checked the pressure before as best I could. It was hard to understand the service manual instructions on how to move the levers to see what my pressure is (looked to be 170 psi). I found the proper yoga position needed to adjust the spring tension, and added tension. The 3 pt then raised the mower with weight completely. I gauged it again and found the pressure to still be 170ish.

Any thoughts/ advice if increasing the spring tension on the relief valve would raise pressure? Or how to accurately gauge the pressure? Or was my problem just the leaking hoses, and not enough spring tension?

BTW...adding 600 pounds to the rear of the mower is not recommended! There was a lot of flex on the mower lift points...but at least it worked for what I needed.

Any thoughts/ advice if increasing the spring tension on the relief valve would raise pressure? Or how to accurately gauge the pressure? Or was my problem just the leaking hoses, and not enough spring tension?

BTW...adding 600 pounds to the rear of the mower is not recommended! There was a lot of flex on the mower lift points...but at least it worked for what I needed.