Hi, as I mentioned to PTfarmer, if you really want to do work with a loader then it is best to buy a 4 wheel drive loader

tractor with full power steering, a heavy axle and pump, shuttle shift, etc. If you are like me and like older equipment, then

the next best step would be to buy an industrial version of the MF135 that has the heavy front axle, pump and power steering,

like the MF202 workbull or the Ford 1801. Those were made to use and handle a loader. I had an old Case 480CK like that, with

a shuttle shift, and although it was 2 wheel drive it was a real loader tractor with a 3 pt. hitch that could lift a mountain.

Now, if you really want to do this, here are my recommendations. Keep in mind that I do not know if you have the swept back

axles or the MF135 with the later straight axle. The later version is probably stronger. I also do not know if the kit you are

looking at is the newer version that has two new steering arms that attach to the spindles (the left one being a dogleg version

onto which you attach the cross connector to have the left spindle turn the right spindle without any welding onto the spindles)

or my older version that required welding of the two heavy 1" thick connectors to the spindles. I also do not know the exact

dimensions of the Davis 102 loader, but I think it is a bit bigger and heavier than my Schwartz 1200 loader, which is the same

as the Ford 770 B. That is a light duty loader but it is strong enough to do routine chores, some digging, etc. without

overwhelming the tractor. Either way, here goes:

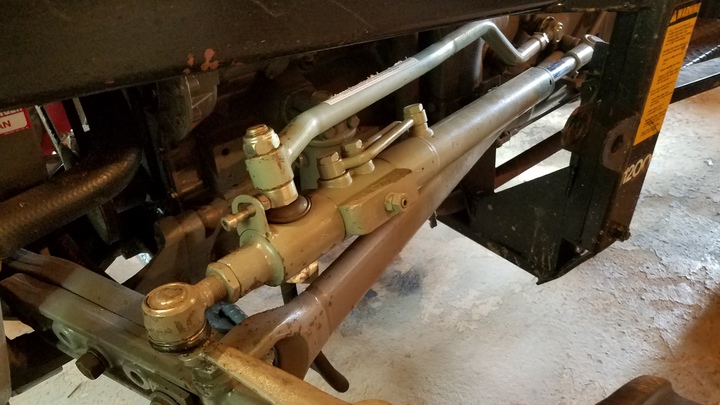

1. My loader inside width at the lower lift cylinders is 34" wide, and the pivot point pin for the lower cylinders is 25" from

the ground. My lift cylinders for the loader are 2" wide. I installed the kit on the tractor before I installed a loader

(about 8 years ago) and I had my front wheels spaced one hole further apart than you see them in the pics. When I went to

install the loader frame I could see that the loader lift cylinder on the left side would rub against the new hydraulic ram when

the front axle would lift up as you went over a bump. That is because the ram is attached to the left axle connector in the

rear and to the left spindle up front so that it moves up and down with the axle. I then had to move the front wheels in closer

together to stop any potential rubbing. I have them set now so that there are two holes showing on the front spindles. See the

pics. The hydraulic ram does not hit the lift cylinder now and there is plenty of clearance.

2. To start the process, move the front wheels into the narrowest pattern that will work for your loader. In my case, it

required a spacing of two holes showing on the axle. Yours may be different. Turn your steering wheel straight ahead and make

sure that your steering sectors are adjusted properly. Now, with the ram off of the tractor, fully extend and close it so that

you know the stroke of the ram. Set the ram so that it is half exposed (i.e., at half stroke), and set the tie rod ends half

in. This will ensure that when you turn the wheel and the ram either retracts or extends it has the maximum stroke to turn left

or right as needed, and the adjustments for the tie rods at the ends can be screwed in or out to fine tune the adjustments for

stroke, steering, etc.

3. Remove the left tie rod connector between the steering arm on the spindle and the other end attached to the steering sector.

Place the front tie rod of the ram in the front spindle and see where the back tie rod ends up against the left wishbone

connector to the front axle. This will tell you where to weld the plate to that connector into which the back tie rod of the

ram will sit. Weld that on and place the ram tie rods into the spindle at front, and the welded plate at the back. Make sure

that you have no clearance problems.

4. Attach the link in the kit that goes between the steering arm sector and the control valve at the front of the ram.

5. Attach the pump on the right side and attach the lines. Fill with 20W oil. Lift the front end of the tractor off the

ground and start it and move the wheel back and forth to get the oil into the ram and remove all air. You now have power assist

steering to the left spindle.

6. The weak, and very weak, link in the kit is the connection and connector between the left and right spindles. You do not

need to remove the right side tie rod connector. Instead, you can leave it on and just have the ram assist on the left side.

That assist will partially assist on the right side because the steering sectors are someone connected within the steering

housing. If you do this you will have about 50% power steering assist. The assist will help in both turning right and left,

but it is only about 50% assist. I tried this when my left to right spindle bent and broke and it works, but it is not true PS.

It is probably stronger that way.

7. If you want to take off the right side steering, like I did, then remove the right side tie rod and attach the left spindle

to the right spindle using the connector in the kit. This connector causes the left spindle to turn the right spindle. There

is tremendous force and tension/compression in that connector when you turn the wheel since one spindle is turning both wheels,

and if the right wheel is in a rut and you try to turn the wheel that left-to-right connector from the kit will bend and break.

I guarantee it. I had to weld heavy 2.5" T bar to the connector to beef it up. It works now and I have confidence in it. It

has been that way for years now. PS - I did all of my welding with a cheap Harbor Freight 90 amp 110v welder! It took long to

do so but with proper prep and angling the pieces to allow a full weld, it worked, even on the heavy 1" thick pieces welded to

the spindles which must be under tremendous forces. Nothing has broken.

8. Then once you have it together, use the tie rod ends to fine tune it so that the steering is straight.

9. PTfarmer correctly states that this system changes the so called Ackerman angle. However, that steering angle issue is very

critical for cars, etc., but since you are only going 3 to 6 mph, I doubt that it affects the tractor steering that much. I

have not noticed any issues.

See some pics attached again that I hope help.

Let me know if you have any other questions, and good luck! Keep us posted.