Ok Long story short. Perkins diesel in a 135. Something went Kaploey on startup last week. I pulled the head today and no dropped valve. Pistons appear ok from the top. I can only hand crank maybe 1/2 a revolution then it binds up. Outside 2 pistons are moving the middle one just laughs at me. I'm assuming I have a broken rod. I'm mechanically inclined and have rebuilt small motors but never anything like this. Can I just change a rod? I see i can't just drop the oil pan like in a small block chev. Is this a motor out kinda thing? Is it like a car just unhook / unbolt and lift it out? I have no garage and no lift.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter rkelman

- Start date

Dieseltech

Well-known Member

- Location

- Akron, Indiana

The pan can be removed, but get a service book first as there are some hidden bolts on some Perkins before the pan will drop down..

(quoted from post at 08:36:34 04/21/18) The pan can be removed, but get a service book first as there are some hidden bolts on some Perkins before the pan will drop down..

Thanks for the reply. Does it make sense to just replace 1 rod?

John Deere D

Well-known Member

I have only ever worked on the Perkins A3.152 in the MF FE 35 X.

At the very least:

Purchase the MF / Perkins SERVICE Manual for your Engine:

If it were my $$$$$$$'s, Use an OUTSIDE MICROMETER and check the Diameters of all connecting rod Journals:

Install all new Conn. Rod bearing shells and check clearances with Plastiqaue:

It's you $$$$$$$$$$$'S

What is the known TTSN running hrs. on this engine?

What is the known running hrs. on this engine since a Major overhaul?

All the best:

Bob. Owner Operator MF FE 35 X...A3.152 Perkins Diesel:

At the very least:

Purchase the MF / Perkins SERVICE Manual for your Engine:

If it were my $$$$$$$'s, Use an OUTSIDE MICROMETER and check the Diameters of all connecting rod Journals:

Install all new Conn. Rod bearing shells and check clearances with Plastiqaue:

It's you $$$$$$$$$$$'S

What is the known TTSN running hrs. on this engine?

What is the known running hrs. on this engine since a Major overhaul?

All the best:

Bob. Owner Operator MF FE 35 X...A3.152 Perkins Diesel:

(quoted from post at 09:16:35 04/21/18) I have only ever worked on the Perkins A3.152 in the MF FE 35 X.

At the very least:

Purchase the MF / Perkins SERVICE Manual for your Engine:

If it were my $$$$$$$'s, Use an OUTSIDE MICROMETER and check the Diameters of all connecting rod Journals:

Install all new Conn. Rod bearing shells and check clearances with Plastiqaue:

It's you $$$$$$$$$$$'S

What is the known TTSN running hrs. on this engine?

What is the known running hrs. on this engine since a Major overhaul?

All the best:

Bob. Owner Operator MF FE 35 X...A3.152 Perkins Diesel:

The hours are about 5200. I dont know how long since a Major overhaul. I don't know any of the history. I can tell someone with a tool kit that consists of a hammer / screwdriver and an adjustable wrench has been in there. Thanks for the info!

Ok Sump is off and its not a Rod. The piston is moving i just couldnt tell from where it was at in the stroke and not being able to watch/turn the motor over at the same time. I think its more like 1/8 a revolution i can get out of it. Where do I go from here? Yes i did check the alternator / water pump are free. Timing gears? Oil pump? Clutch?

Brendon Warren

Well-known Member

Kaplooey on start up? Did you pull your starter off? Maybe the nose

cone broke and is binding you up.

cone broke and is binding you up.

John Deere D

Well-known Member

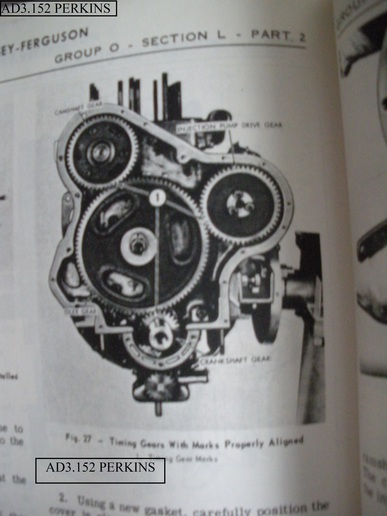

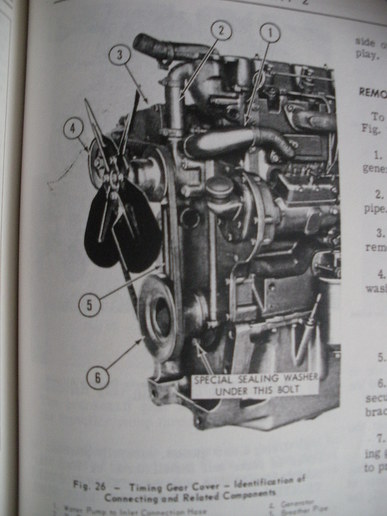

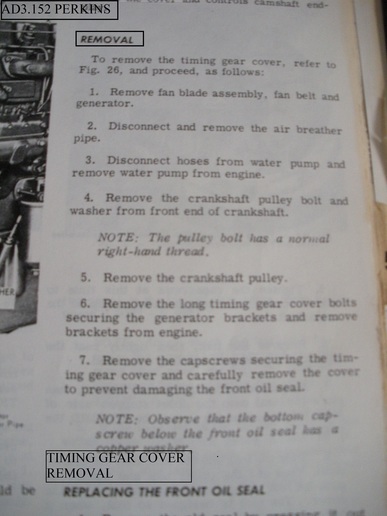

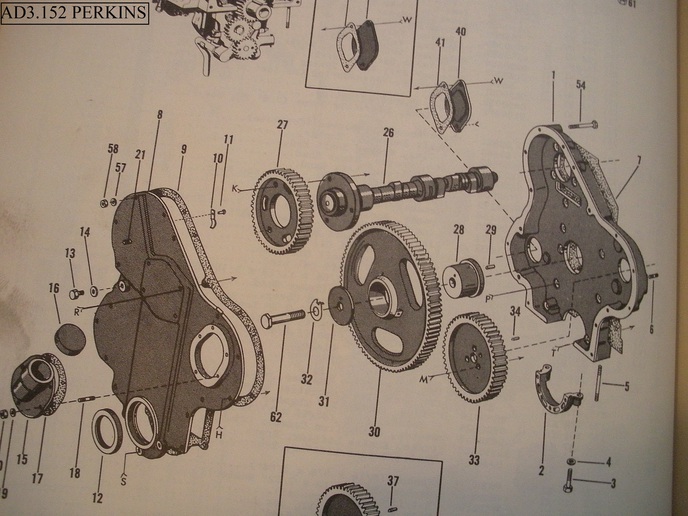

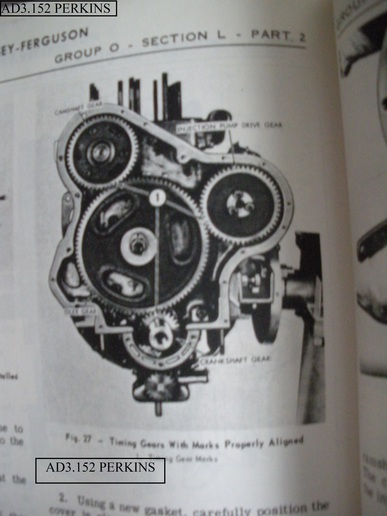

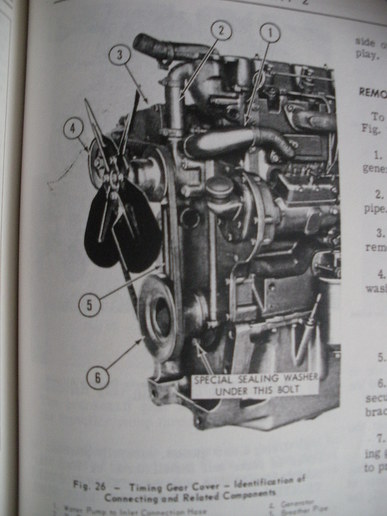

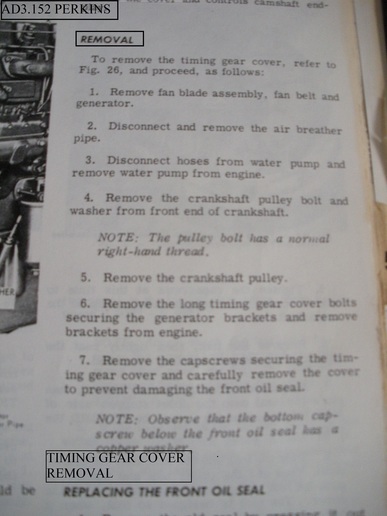

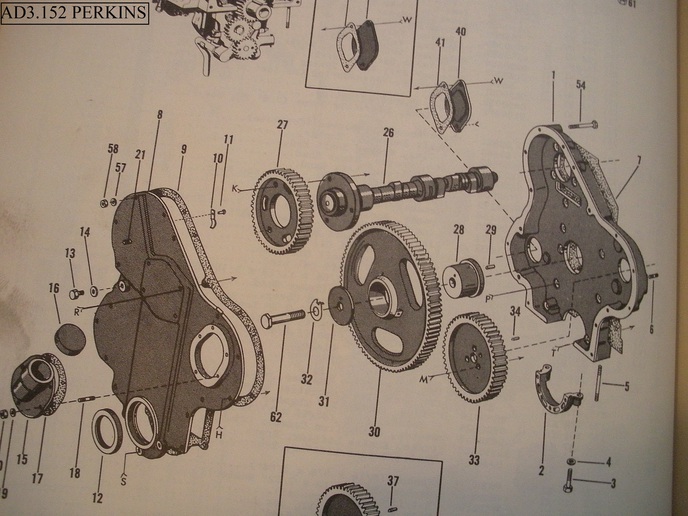

In case the Timing Cover has to be removed?????????

(quoted from post at 17:37:01 04/21/18) Kaplooey on start up? Did you pull your starter off? Maybe the nose

cone broke and is binding you up.

Hey Thanks for the reply. Starter is off.

Dieseltech

Well-known Member

- Location

- Akron, Indiana

Did you try and see if the engine turns over with the clutch pedal blocked COMPLETELY DOWN? Might not be an engine issue, but a transmission problem. I had a 165 diesel with a thumping noise in the transmission, the PTO driven gear had two teeth off. Any piece of gear teeth in the wrong spot WILL stop the gears from turning, no matter if engine or transmission..

(quoted from post at 05:19:12 04/22/18) Did you try and see if the engine turns over with the clutch pedal blocked COMPLETELY DOWN? Might not be an engine issue, but a transmission problem. I had a 165 diesel with a thumping noise in the transmission, the PTO driven gear had two teeth off. Any piece of gear teeth in the wrong spot WILL stop the gears from turning, no matter if engine or transmission..

I just had my wife push the clutch down and it does turn over. So its not in the engine. The pto spins freely in neutral. Now what? I would like to put the engine together so i dont have EVERY bolt out of my tractor but i guess i better figure out whats wrong first.

DavidP, South Wales

Well-known Member

Hello, no-one has yet suggested that it

might be the common problem with 35/135

transmissions....that of the loose gear

lever. Being able to turn the engine freely

with the clutch pedal down would certainly

tie in with this. It is possible that the

problem namely the gear lever ball coming

out of the selector slot happened when you

shifted to neutral on its last use. If the

brakes are applied this would give the

symptoms of a drive-line lock-up. When you

move the main gear lever in neutral and

engage gear is there a lot of slop in the

lever? If you remove the oil filler cap

next to the main gear lever and using a

flashlight look inside you should be able

to see if the two selectors are in line

when the tractor is in neutral. If not then

it is a simple job using a large

screwdriver to realign them.

Just a thought.

DavidP, South Wales

might be the common problem with 35/135

transmissions....that of the loose gear

lever. Being able to turn the engine freely

with the clutch pedal down would certainly

tie in with this. It is possible that the

problem namely the gear lever ball coming

out of the selector slot happened when you

shifted to neutral on its last use. If the

brakes are applied this would give the

symptoms of a drive-line lock-up. When you

move the main gear lever in neutral and

engage gear is there a lot of slop in the

lever? If you remove the oil filler cap

next to the main gear lever and using a

flashlight look inside you should be able

to see if the two selectors are in line

when the tractor is in neutral. If not then

it is a simple job using a large

screwdriver to realign them.

Just a thought.

DavidP, South Wales

Dieseltech

Well-known Member

- Location

- Akron, Indiana

I'm guessing tractor has the two stage clutch. If the transmission has damage on the PTO input side, engine will turn over with clutch pedal fully down, but stop again with the first stage, 1/2 way down which releases the main disc only. Tractor will start and run fine IF the hi-lo lever is in the center/start position, even if the R123 shift lever is stuck in reverse. IF there's a shift for broken, allowing two gears to mesh at once that can be verified by engine turning fine with the clutch pedal down 1/2 way also, and stop again with the pedal up. Have seen shift forks broken before, but not common. If you like call me some evening, 574 835 3292, old, semi-retired MF mechanic..

(quoted from post at 08:42:03 04/22/18) Hello, no-one has yet suggested that it

might be the common problem with 35/135

transmissions....that of the loose gear

lever. Being able to turn the engine freely

with the clutch pedal down would certainly

tie in with this. It is possible that the

problem namely the gear lever ball coming

out of the selector slot happened when you

shifted to neutral on its last use. If the

brakes are applied this would give the

symptoms of a drive-line lock-up. When you

move the main gear lever in neutral and

engage gear is there a lot of slop in the

lever? If you remove the oil filler cap

next to the main gear lever and using a

flashlight look inside you should be able

to see if the two selectors are in line

when the tractor is in neutral. If not then

it is a simple job using a large

screwdriver to realign them.

Just a thought.

DavidP, South Wales

I'm not sure what is too much slop to be honest. My tractor experience is pretty limited. I'll check this though thanks!

It seems to be working ok. I cant see over far enough to see the high / low although it feels fine. I did notice however it goes into every gear BUT second. That doesnt really surprise me on a 50 year old gearbox though. A friend at work has a borescope. I'll bring that home tomorrow night and see what i can see from there I guess. [/img]

Dieseltech

Well-known Member

- Location

- Akron, Indiana

That's the Multi-Power high range clutch drum assembly. Tractor needs two splits to get the assembly out, an engine/transmission split, and a trans/diff case joint split. Reason is the main clutch input shaft must go out the rear before the drum assembly can be lifted out..

Dieseltech

Well-known Member

- Location

- Akron, Indiana

That's a cotter pin, it's supposed to be there..

ptfarmer

Well-known Member

- Location

- San Antonio, Tx

The idea behind the cotter pin in the hole is to keep the weep hole from getting clogged up. Vibration, driving over tall grass, weeds, etc makes the cotter pin rotate/move to help keep the weep hole open.

Similar threads

- Replies

- 5

- Views

- 376

- Replies

- 12

- Views

- 506

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy