New pistons, rings, and an new cylinder head (old one was cracked). Put all together and it started up fine. Lots of oil pressure. I ran it for 10 minutes and shut it off. Next day started up ran for 35 minutes and it started to make enough crank case pressure to blow oil out of the dip stick. Today I can’t get it to run at all? Any ideas? Blow ahead gasket maybe? Any help would be appreciated

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Hugel

- Start date

John Deere D

Well-known Member

Make & Model of Engine?

Diesel / Gasoline...?

Bob...Owner MF FE 35 X Diesel

Diesel / Gasoline...?

Bob...Owner MF FE 35 X Diesel

(quoted from post at 22:54:48 01/21/18) Make & Model of Engine?

Diesel / Gasoline...?

Bob...Owner MF FE 35 X Diesel

Sorry, 1961 massey35 Perkins diesel

I’m just not sure why it’s blowing by so badly. Oil level is still good, it’s holding water fine. Before I put new pistons in I checked the cylinders for round and taper and all three were within .002” from zero. I honed the cylinders and cleaned them well before the pistons went in.

Phil Tibbetts

Well-known Member

Did you replace the sleeves? Is the crankcase vent plugged?

John Deere D

Well-known Member

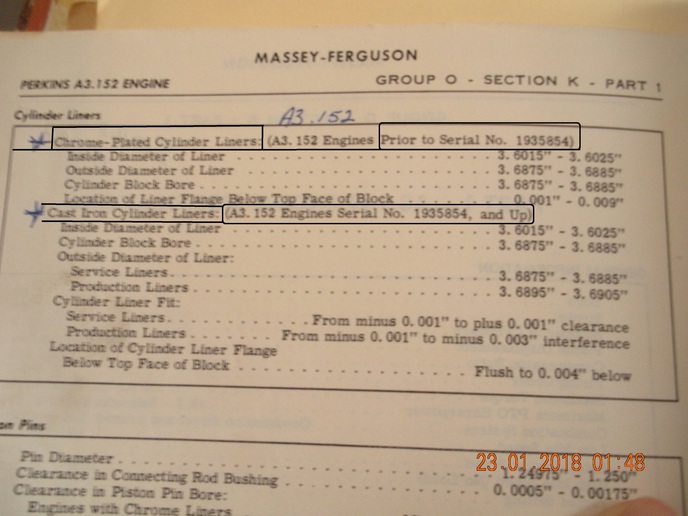

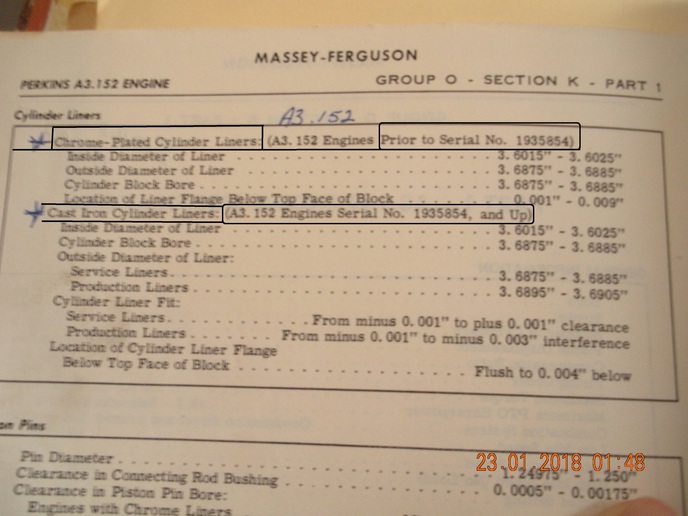

Were the Sleeves CHROME or CAST?

Chrome sleeves .....I always install Cast Rings:

Cast Sleeves I always Install ...Chrome Rings:

Bob..Owner Operator MF FE 35 X 3 cylinder Perkins:

Chrome sleeves .....I always install Cast Rings:

Cast Sleeves I always Install ...Chrome Rings:

Bob..Owner Operator MF FE 35 X 3 cylinder Perkins:

ptfarmer

Well-known Member

- Location

- San Antonio, Tx

If you just hone the cylinders you usually use cast iron piston rings. When you hone a cylinder you are only removing the glaze, but the cylinder bores are still hard from all the hot, and cold cycles over the years so you have to use the "soft" cast iron piston rings so the rings will seat in, and seal. When you have a engine bored, or put in new sleeves the cylinders are "soft" again so you can use piston rings with coated "hard" piston rings (the cylinder bores will seat in). On engines with chrome cylinder sleeves I'll change the sleeves, pistons, and rings in a kit if needed.

John Deere D

Well-known Member

I should have mentioned. I have always changed the sleeves, pistons, and rings as a unit, on a Perkins A3.152 Diesel Engine: I never have changed out only the Pistons and Rings.

There is a 99.99% chance your engine has Sleeves as per the serial # of the engine. However, there are updated SLEEVES that are machined to change out the CHROME SLEEVES and install Cast Iron Sleeves.

It will be interesting to know what material the sleeves are in your Engine?

Bob....

There is a 99.99% chance your engine has Sleeves as per the serial # of the engine. However, there are updated SLEEVES that are machined to change out the CHROME SLEEVES and install Cast Iron Sleeves.

It will be interesting to know what material the sleeves are in your Engine?

Bob....

Phil Tibbetts

Well-known Member

You could have got sleeves pistons and ring set for probably about the same price as the pistons and rings. I would never replace just the pistons and rings. IMO

Phil Tibbetts

Well-known Member

Another thing, even though there didn't seem to be any ridge there is a possibility that a very minute ridge together with new rings and pistons ( no guarantee the ring grooves were in the exact sane spot) and with the new rings having a relatively sharp edge you might have broken rings. IMO

John Deere D

Well-known Member

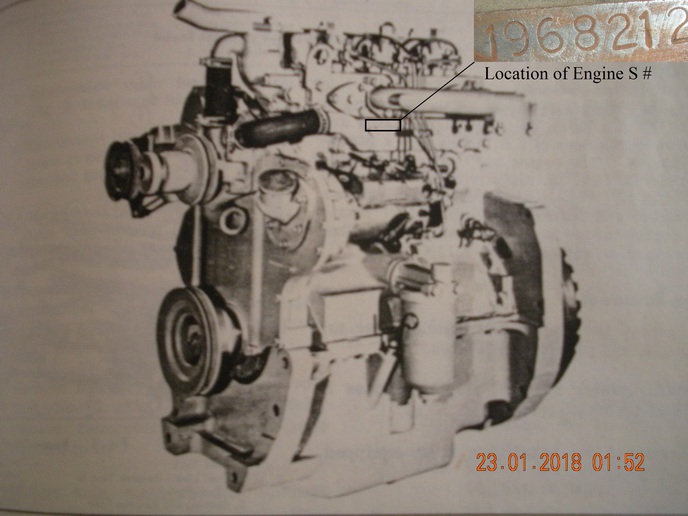

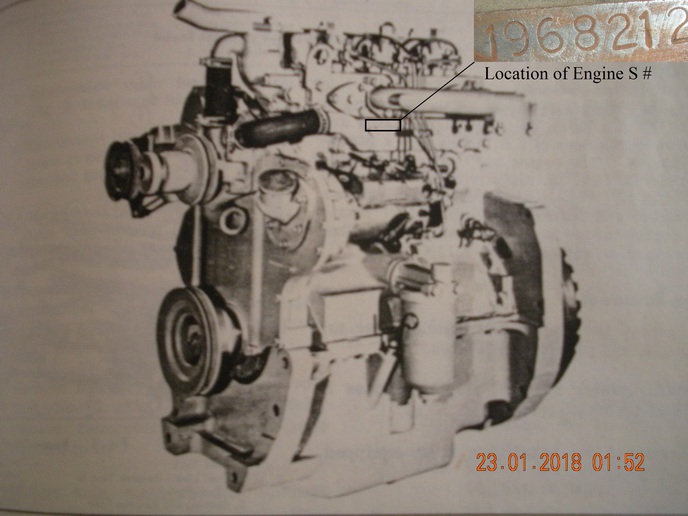

This is the ENGINE SERIAL # on my MF FE 35 X 1963:

When you check the SERIAL # on your Perkins Engine you can then trace down the OEM sleeve configuration.....Chrome or Cast Steel??

When you check the SERIAL # on your Perkins Engine you can then trace down the OEM sleeve configuration.....Chrome or Cast Steel??

(quoted from post at 11:21:02 01/23/18) This is the ENGINE SERIAL # on my MF FE 35 X 1963:

When you check the SERIAL # on your Perkins Engine you can then trace down the OEM sleeve configuration.....Chrome or Cast Steel??

I track the dash vin tag down as a 1961. Not sure if that will tell us what the sleeves are

ptfarmer

Well-known Member

- Location

- San Antonio, Tx

Perkins diesel, chrome liners used prior to engine serial number 1829891.

835756M91 Piston Assembly (Perkins No. 59156) (Original part number 732650M91)

732638M1 Liner, Cylinder Block (Piston Sleeve) (Perkins No. 31358308)

Perkins diesel, chrome liners used in engine serial numbers 1829891 thru 1935853.

835756M91 Piston Assembly (Perkins No. 59634) (Original part number 733147M91)

732638M1 Liner, Cylinder Block (Piston Sleeve) (Perkins No. 31358308)

Perkins diesel, cast iron lines used in engine serial number 1935854, and up.

734459M91 Piston Assembly, Complete (Perkins No. 81874)

734175M1 Liner, Cylinder Block (Piston Sleeve) (Cast Iron) (Perkins No. 31358322)

835756M91 Piston Assembly (Perkins No. 59156) (Original part number 732650M91)

732638M1 Liner, Cylinder Block (Piston Sleeve) (Perkins No. 31358308)

Perkins diesel, chrome liners used in engine serial numbers 1829891 thru 1935853.

835756M91 Piston Assembly (Perkins No. 59634) (Original part number 733147M91)

732638M1 Liner, Cylinder Block (Piston Sleeve) (Perkins No. 31358308)

Perkins diesel, cast iron lines used in engine serial number 1935854, and up.

734459M91 Piston Assembly, Complete (Perkins No. 81874)

734175M1 Liner, Cylinder Block (Piston Sleeve) (Cast Iron) (Perkins No. 31358322)

John Deere D

Well-known Member

Info from Massey Ferguson "MASSEY DEALER SHIP" SERVIVE MANUAL"

John Deere D

Well-known Member

I sent you Two pictures on 01-23-2018 13:30:31:

(1)Please post back on "YT" the SERIAL NUMBER as per the ENGINE picture I posted for you,as to the location of the ENGINE SERIAL N0.

The serial NUMBER on the engine ( as per picture you were sent) shall indicate what material the SLEEVES were when the engine was new:

The DASH serial number may NOT be indicative of the engine year of manufacture...Engines from time to time are swapped out???

(2) Check the MF 35 service manual (as per picture I sent you)as per ENGINE SERIAL NUMBER versus SLEEVE composition.. e.g.. Chrome or Cast.........?

Bob...Retired Power engineer...Owner operator MF FE 35 X...

(1)Please post back on "YT" the SERIAL NUMBER as per the ENGINE picture I posted for you,as to the location of the ENGINE SERIAL N0.

The serial NUMBER on the engine ( as per picture you were sent) shall indicate what material the SLEEVES were when the engine was new:

The DASH serial number may NOT be indicative of the engine year of manufacture...Engines from time to time are swapped out???

(2) Check the MF 35 service manual (as per picture I sent you)as per ENGINE SERIAL NUMBER versus SLEEVE composition.. e.g.. Chrome or Cast.........?

Bob...Retired Power engineer...Owner operator MF FE 35 X...

John Deere D

Well-known Member

I'm not able to enlarge the below picture. The Number 3 Ring on the piston,third ring down from top of piston. Is that Ring a ONE piece RIG? When you installed the number three ring was there instructions as to the proper orientation of this ring, as in which side of ring faces up?

Something has caused severe scuffing of the cylinder sleeves, thus the compression is not HIGH enough to generate the HEAT required to create ignition. Diesel is ignited from Heat of Compression.

I have overhauled several A 3.152 Perkins and I do not recall the # 3 ring looking like your picture .

Bob..

Something has caused severe scuffing of the cylinder sleeves, thus the compression is not HIGH enough to generate the HEAT required to create ignition. Diesel is ignited from Heat of Compression.

I have overhauled several A 3.152 Perkins and I do not recall the # 3 ring looking like your picture .

Bob..

ptfarmer

Well-known Member

- Location

- San Antonio, Tx

The top ring is chrome, and the 4th ring is chrome (you have them in the right order).

ptfarmer

Well-known Member

- Location

- San Antonio, Tx

Need to get the piston out to have a look at it along with the rings.

John Deere D

Well-known Member

Something has caused severe scuffing of the cylinder sleeves, thus the compression is not HIGH enough to generate the HEAT required to create ignition? Diesel is ignited from Heat of Compression

Severe scuffing why....?

Did you hone the sleeves before the NEW Pistons and Rings were installed?

Remove pistons......

Bob...

Severe scuffing why....?

Did you hone the sleeves before the NEW Pistons and Rings were installed?

Remove pistons......

Bob...

ptfarmer

Well-known Member

- Location

- San Antonio, Tx

Right before I put a piston in I coat the cylinder with oil, and right before I compress the rings to install them into the cylinder I coat the piston, and rings with lots of oil. I've never rebuilt a Perkins with chrome liners, but I think you shouldn't have honed it.

ilraceu1965

New User

I'm completely new to tractor engines. I'm not new to building engines, mostly SBC street/race engines. Is it possible that he used a different alloy piston that expands at a different rate therefore needing more piston to wall clearance? Or are basically all replacement tractor pistons the same alloy. I could guess that a OE Perkins piston might be different than a China/ India replacement.

John Deere D

Well-known Member

Hugel.....did you ever remove pistons and decide on the problem?

Just wondering........

Thanks...

Bob....

Just wondering........

Thanks...

Bob....

Similar threads

- Replies

- 1

- Views

- 186

- Replies

- 5

- Views

- 469

- Replies

- 2

- Views

- 376

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy