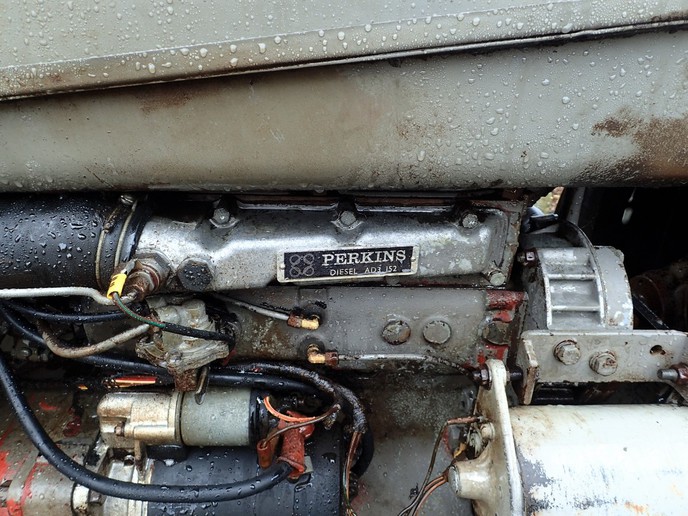

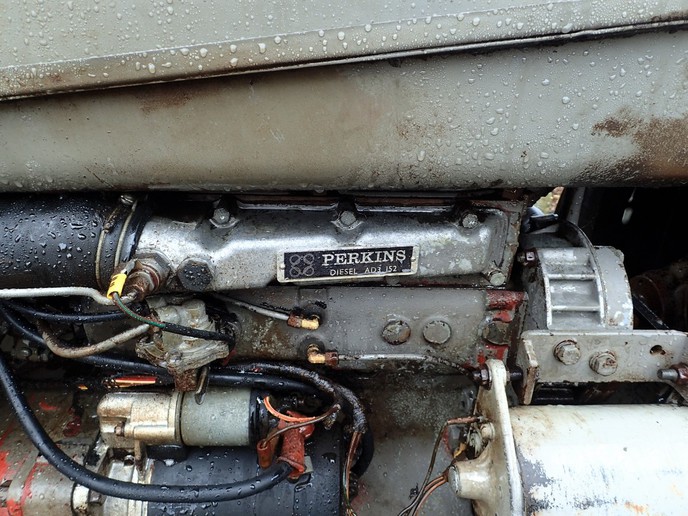

Got some photos of my restoration (not finished yet!) of my 1967 MF 135, that has been in the family from new. Made in Coventry,

England, Perkins AD3 152, Mechanically good, but tin work, wheels etc pretty rusty. Tin and wheels have been powder coated - local

guys made a great job. Have fitted a ROPS 'cos the grandkids will learn to drive it. Will restore and re-fit the MF80 loader at the

end.Hope some of you guys find it interesting!

Jim (Scotland)

England, Perkins AD3 152, Mechanically good, but tin work, wheels etc pretty rusty. Tin and wheels have been powder coated - local

guys made a great job. Have fitted a ROPS 'cos the grandkids will learn to drive it. Will restore and re-fit the MF80 loader at the

end.Hope some of you guys find it interesting!

Jim (Scotland)