I had a thread awhile back about losing oil pressure after warming up, engine cold-start is a solid 50psi, after 30 minutes or so it will drop to 5-10 or less. No knocks, noises, runs great and no smoke. Anyway I have finally opened a place in the shop to start tearing this MF 245 apart.

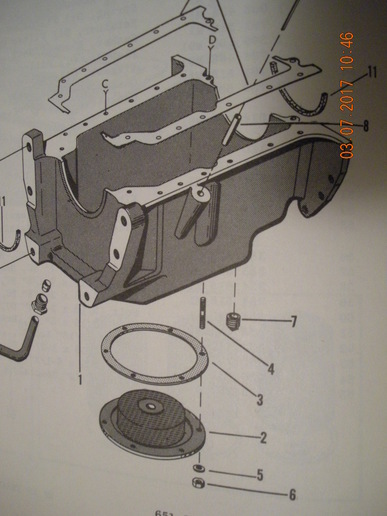

The only thing I have done so far is removing the round plate on the bottom of the pan. I found quite a bit of bearing shavings and slivers, I assume most of it is thrust bearing material. I eyeballed crankshaft end play and its around 1/8" :shock:. Looks like its time to plan a split, engine removal and rebuild???

[/url]

The only thing I have done so far is removing the round plate on the bottom of the pan. I found quite a bit of bearing shavings and slivers, I assume most of it is thrust bearing material. I eyeballed crankshaft end play and its around 1/8" :shock:. Looks like its time to plan a split, engine removal and rebuild???

[/url]