wannaspeed

New User

I was looking at another thread here with the same question from 8 years ago, I tried to reply but was unable due to the archive. So I'm posting a new thread.

I have a Massey Ferguson MF 30B industrial with 3pt, shuttle shift instant reverse, and loader. I would like to add PTO. I've seen several threads that say its not terribly difficult, but no one actually does it, nor posts really how. Everything is always rather vague.

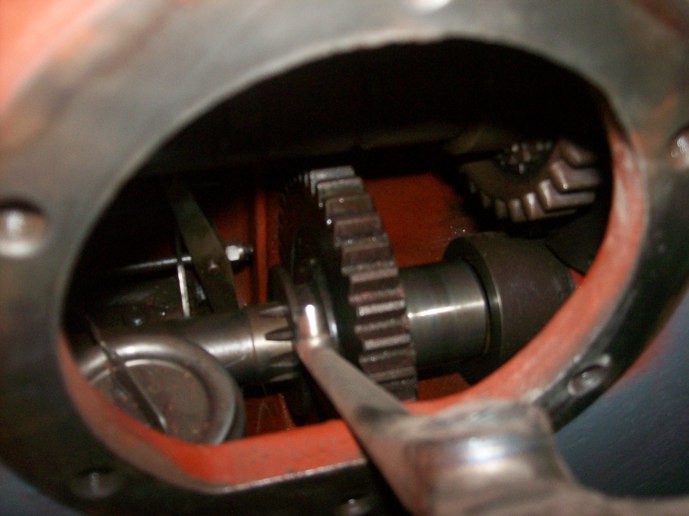

Is it just a matter of unbolting the cover plate on the back, sliding the shaft in and bolting it up, then adding the lever assembly on the left? Is there additional bearings or gears that have to be added? Plugs that need removed?

I understand the PTO will run backwards in reverse and an over run clutch will need to be installed on the pto spline. What else? If someone can get me headed in the right direction i'll do it and take pics of the process.

I have a Massey Ferguson MF 30B industrial with 3pt, shuttle shift instant reverse, and loader. I would like to add PTO. I've seen several threads that say its not terribly difficult, but no one actually does it, nor posts really how. Everything is always rather vague.

Is it just a matter of unbolting the cover plate on the back, sliding the shaft in and bolting it up, then adding the lever assembly on the left? Is there additional bearings or gears that have to be added? Plugs that need removed?

I understand the PTO will run backwards in reverse and an over run clutch will need to be installed on the pto spline. What else? If someone can get me headed in the right direction i'll do it and take pics of the process.