Hello,

I have a 1967 MF 135 with the AG3.152 Perkins Diesel engine. I have been experiencing loss of oil pressure on the tractor. Fires up great, and starts @ around 60 and slowly drops down to 10 over the course of operating. Based on advice I found here and elsewhere I decided to try replacing the oil pump (thinking the overpressure spring was stuck open, or oil pump otherwise shot). This is a good place to say: I am a newbie to working on older tractors but have a decent mechanical know-how.

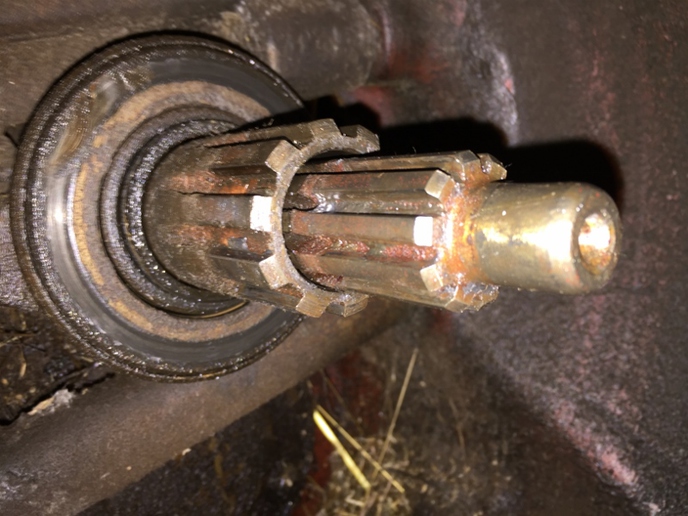

Got the oil pan dropped just fine and was surprised to find an upper and lower thrust washer living in the bottom of the oil pan (yay! - not). I am proceeding with oil pump replacement since I already have the parts and pan off, but now I am wondering about replacing the thrust washer (and if maybe oil seepage here was causing loss of pressure - although tractor leaves a very minor oil spot its not much).

Is it possible to remove the rear main bearing cap to replace the thrust washer without splitting? It appears visually and in diagrams to be secured to the rear main oil seal plate by 3 screws that I cant access very well currently. Also, I think I can see the spot in the rear main bearing cap where the thrust washer sits, but I am assuming I need to get the cap off to get it seated in there properly (? like I said - newbie).

Hate to split the tractor just to replace a $3 part as the main bearings have already been renewed shortly before I bought the tractor (Although I am now questioning how good of a job they did given that this thrust washer obviously wasn't secured properly, or blew out due to crank walk). Any thoughts or creative tips on how I can get over this hurdle?

Thanks to everyone that posts here, this has been an amazing resource to help me learn!

- Andrew

I have a 1967 MF 135 with the AG3.152 Perkins Diesel engine. I have been experiencing loss of oil pressure on the tractor. Fires up great, and starts @ around 60 and slowly drops down to 10 over the course of operating. Based on advice I found here and elsewhere I decided to try replacing the oil pump (thinking the overpressure spring was stuck open, or oil pump otherwise shot). This is a good place to say: I am a newbie to working on older tractors but have a decent mechanical know-how.

Got the oil pan dropped just fine and was surprised to find an upper and lower thrust washer living in the bottom of the oil pan (yay! - not). I am proceeding with oil pump replacement since I already have the parts and pan off, but now I am wondering about replacing the thrust washer (and if maybe oil seepage here was causing loss of pressure - although tractor leaves a very minor oil spot its not much).

Is it possible to remove the rear main bearing cap to replace the thrust washer without splitting? It appears visually and in diagrams to be secured to the rear main oil seal plate by 3 screws that I cant access very well currently. Also, I think I can see the spot in the rear main bearing cap where the thrust washer sits, but I am assuming I need to get the cap off to get it seated in there properly (? like I said - newbie).

Hate to split the tractor just to replace a $3 part as the main bearings have already been renewed shortly before I bought the tractor (Although I am now questioning how good of a job they did given that this thrust washer obviously wasn't secured properly, or blew out due to crank walk). Any thoughts or creative tips on how I can get over this hurdle?

Thanks to everyone that posts here, this has been an amazing resource to help me learn!

- Andrew