Vineyard_65

Member

PHOTOS of rebuilding my Massey’s Power Steering Cylinder

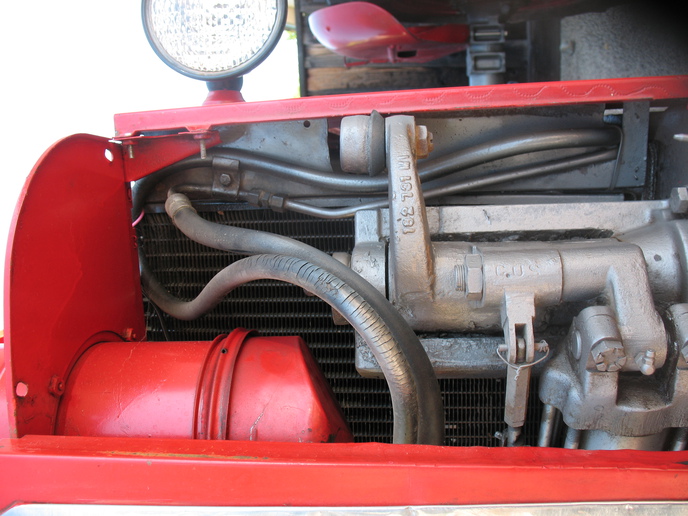

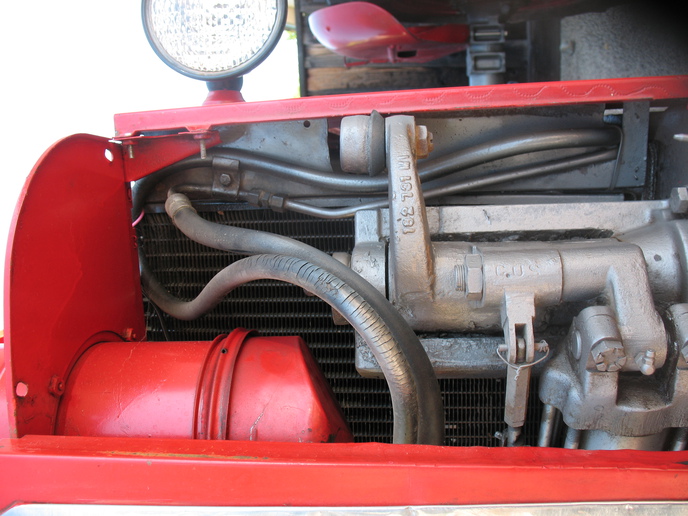

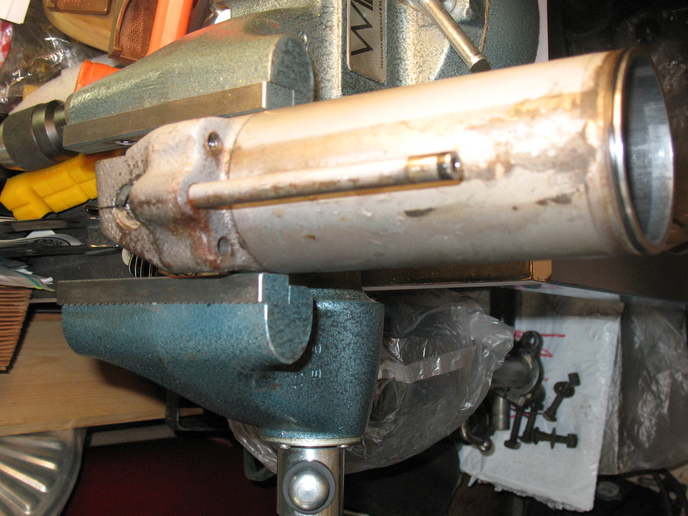

I took some pictures of the rebuild process for the power steering cylinder

On my ‘64 MF-65 Dieselmatic. It was leaking a bunch of fluid prior to the rebuild.

Hopefully this might be useful for some of the other folks out there.

Notes/Comments:

1- Baum Hydraulics in Nebraska is great for hydraulic parts and extremely knowledgeable. Their rebuild kit was $17 & USA made compared to $54 for the Sparex kit. btw, I’m ok with British parts but given current events, trying to support the home team wherever possible.

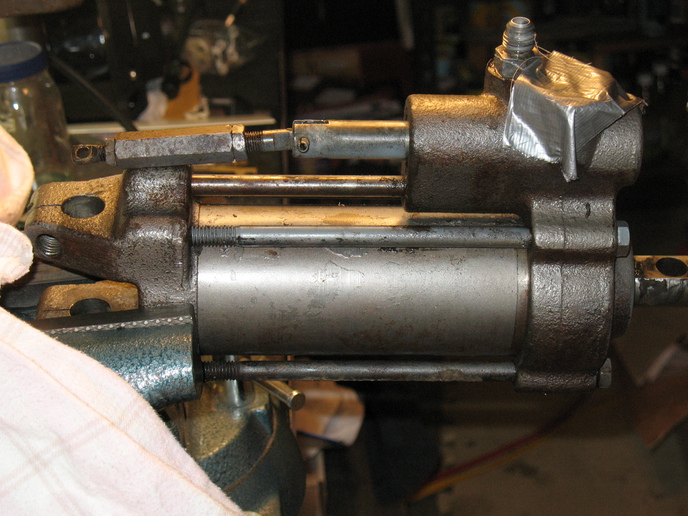

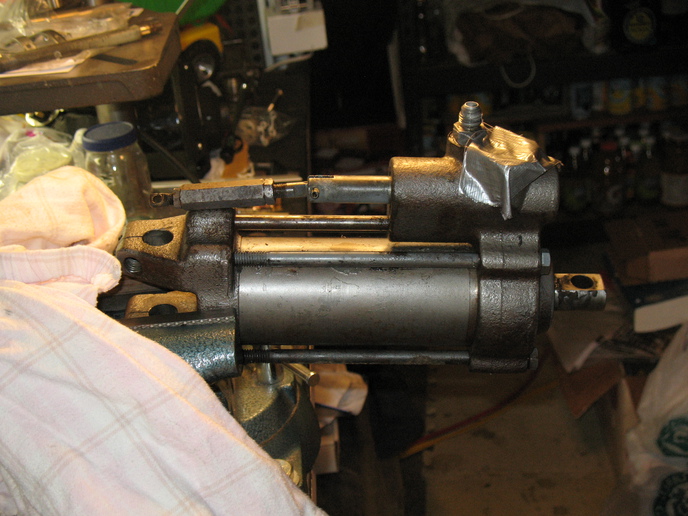

2- The most challenging aspects of the rebuild were disassembling the valve body and installing the internal scraper seals inside the valve body casting.

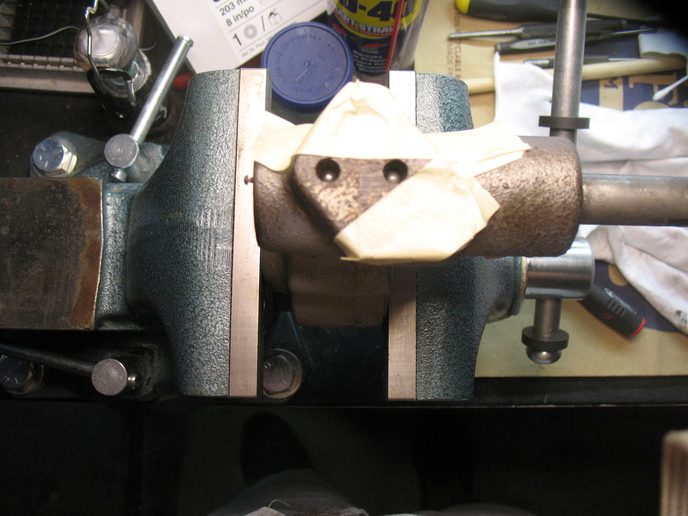

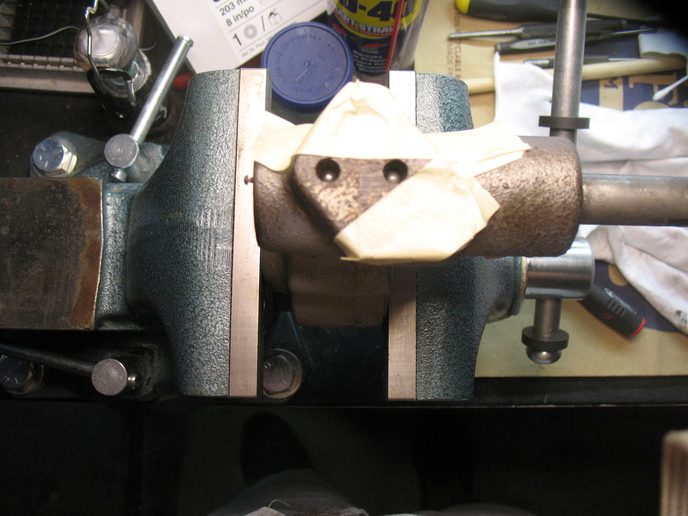

a. Taking the valve body apart was challenging because someone before me drove hardened Ball Bearings in the Allen screw holes(see pic) on top of the valve assembly. These are access holes which allow you insert a punch in the spool body, so that you can keep it from spinning when you try to unscrew the valve end rod.

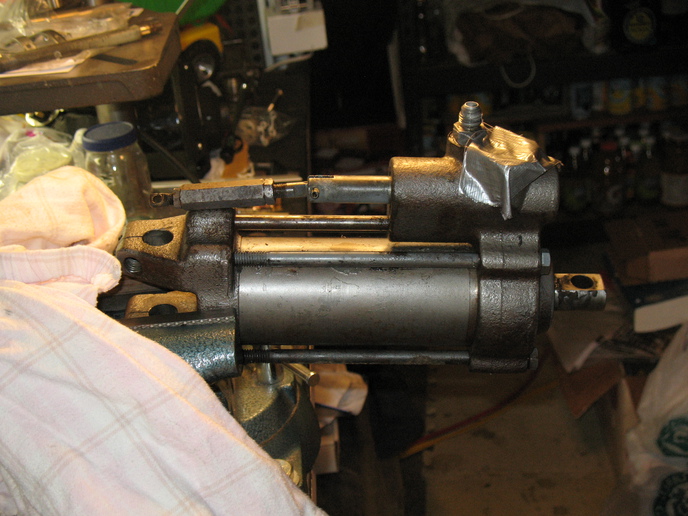

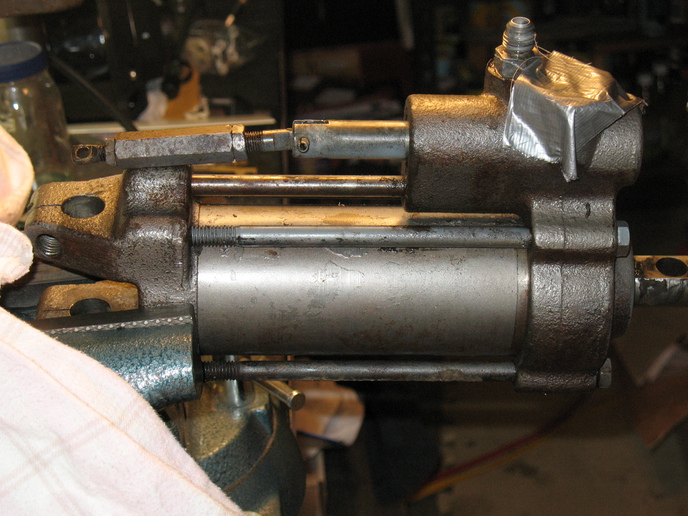

b. One of the pics show the mess I made of the valve seal when I was trying remove it with the rod still in place

c. Note to self: best way to remove a steel framed seal when something is in the hole is to take a puncture wound punch and to deform the seal inward, towards the center. If you push in one side, then the opposite side, alternating around the seal it’s pretty painless to remove. That was, of course, the 4th and last thing I tried after first attempting pullers, small chisels & drilling.

d. I had polish the valve rod in a drill press with some fine sand paper after munging it up trying to pull the seal out.

e. Yes, I tried to remove the pressed in ball bearings with a hardened puncture wound punch and cobalt drill bits, but it wasn’t happening.

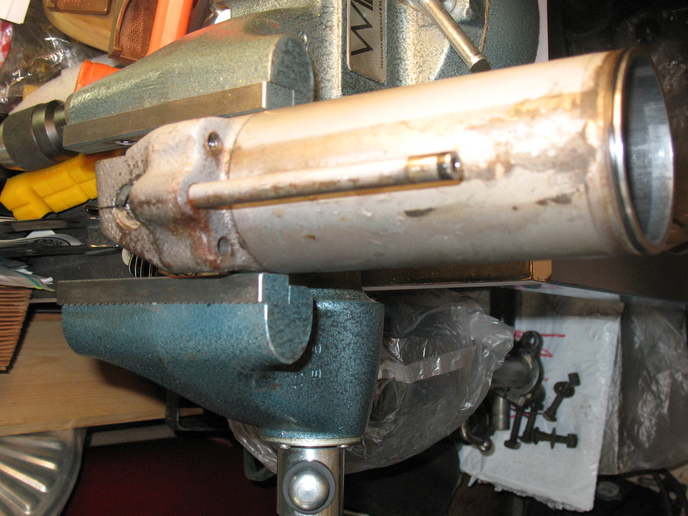

3- Degreased and stripped the outside parts with a wire wheel to avoid getting grit inside & not being able to remove all of it. Blasting would have been a lot more fun.

4- I replaced both the pins attaching the cyl connecting rod to the mounting bracket and the pin attaching the other end of the assembly to the steering arm. That was probably a waste of money. Unless your existing pins are severely damaged, the clearances are so large that there was no appreciable benefit and I was out an extra $60.

5- Use Grease on all the O-rings, seals, and rods when assembling the cylinder.

6- The local Parker store was able to put together replacement hydraulic lines for ~$100.00

7- I replaced the PS filter with a new Baldwin one I found on eBay and used Napa type FA ATF for fluid. Used the Massey on Saturday for a long time and all seemed to seal and run great, by God’s grace.

8- Thanks everyone on the forum for there input.

Off to the next project: trying to fix the dripping diesel between the fuel tank bung & petcock and above the injectors…

I took some pictures of the rebuild process for the power steering cylinder

On my ‘64 MF-65 Dieselmatic. It was leaking a bunch of fluid prior to the rebuild.

Hopefully this might be useful for some of the other folks out there.

Notes/Comments:

1- Baum Hydraulics in Nebraska is great for hydraulic parts and extremely knowledgeable. Their rebuild kit was $17 & USA made compared to $54 for the Sparex kit. btw, I’m ok with British parts but given current events, trying to support the home team wherever possible.

2- The most challenging aspects of the rebuild were disassembling the valve body and installing the internal scraper seals inside the valve body casting.

a. Taking the valve body apart was challenging because someone before me drove hardened Ball Bearings in the Allen screw holes(see pic) on top of the valve assembly. These are access holes which allow you insert a punch in the spool body, so that you can keep it from spinning when you try to unscrew the valve end rod.

b. One of the pics show the mess I made of the valve seal when I was trying remove it with the rod still in place

c. Note to self: best way to remove a steel framed seal when something is in the hole is to take a puncture wound punch and to deform the seal inward, towards the center. If you push in one side, then the opposite side, alternating around the seal it’s pretty painless to remove. That was, of course, the 4th and last thing I tried after first attempting pullers, small chisels & drilling.

d. I had polish the valve rod in a drill press with some fine sand paper after munging it up trying to pull the seal out.

e. Yes, I tried to remove the pressed in ball bearings with a hardened puncture wound punch and cobalt drill bits, but it wasn’t happening.

3- Degreased and stripped the outside parts with a wire wheel to avoid getting grit inside & not being able to remove all of it. Blasting would have been a lot more fun.

4- I replaced both the pins attaching the cyl connecting rod to the mounting bracket and the pin attaching the other end of the assembly to the steering arm. That was probably a waste of money. Unless your existing pins are severely damaged, the clearances are so large that there was no appreciable benefit and I was out an extra $60.

5- Use Grease on all the O-rings, seals, and rods when assembling the cylinder.

6- The local Parker store was able to put together replacement hydraulic lines for ~$100.00

7- I replaced the PS filter with a new Baldwin one I found on eBay and used Napa type FA ATF for fluid. Used the Massey on Saturday for a long time and all seemed to seal and run great, by God’s grace.

8- Thanks everyone on the forum for there input.

Off to the next project: trying to fix the dripping diesel between the fuel tank bung & petcock and above the injectors…