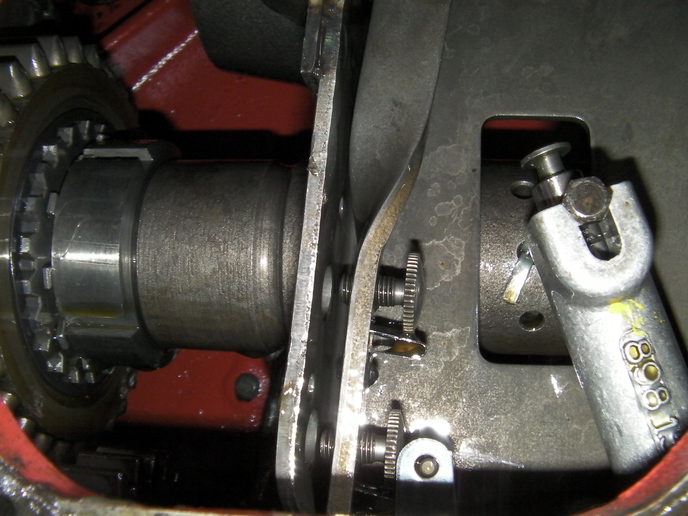

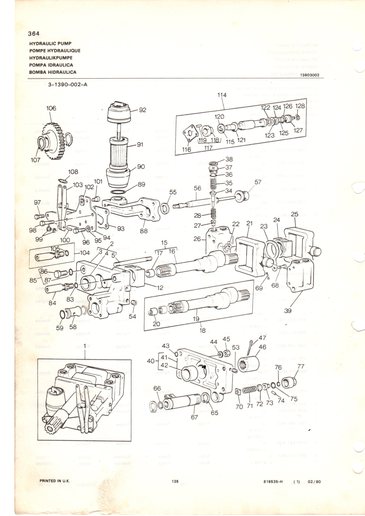

I think the pump is ok because the loader lifts well, but I have always felt that my hydraulics weren't working right and when I tried using a plough the depth control raised and lowered but was not responding correctly.

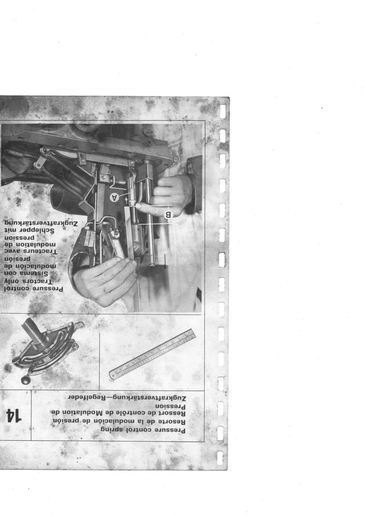

Suspecting the control spring adjustment I removed it to check. Even with a self made tool it took a lot of time and ingenuity to get it out. I think the adjustment was ok, but it wasn't a waste of time as I could fit a new rubber.

My 135 also has pressure control and if I raise the drum mower and move the lever past constant pumping into pressure then it can be lowered, held or raised according to the pressure.

My 165 raises using position (sounds like it's working hard with a round bale on a pallet!) but if you go past constant pumping it does not lower again.

Another symptom is that when the diverter valve is switched to the loader, the link arms slowly sink under the weight of the counterweight.

I have never had the cover off this tractor, although I fitted new top O rings when I changed the diverter valve.

The next step is to have a look inside, but any tips on what to look for which would help to avoid removing the cover would be appreciated.

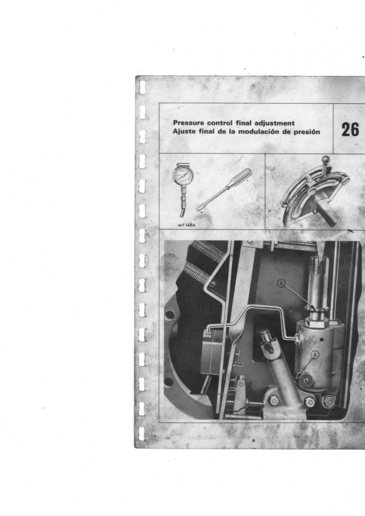

I have kept a lot of notes on adjustment and I have the MF27 manual but I do not have a pressure guage.

Mike.

Suspecting the control spring adjustment I removed it to check. Even with a self made tool it took a lot of time and ingenuity to get it out. I think the adjustment was ok, but it wasn't a waste of time as I could fit a new rubber.

My 135 also has pressure control and if I raise the drum mower and move the lever past constant pumping into pressure then it can be lowered, held or raised according to the pressure.

My 165 raises using position (sounds like it's working hard with a round bale on a pallet!) but if you go past constant pumping it does not lower again.

Another symptom is that when the diverter valve is switched to the loader, the link arms slowly sink under the weight of the counterweight.

I have never had the cover off this tractor, although I fitted new top O rings when I changed the diverter valve.

The next step is to have a look inside, but any tips on what to look for which would help to avoid removing the cover would be appreciated.

I have kept a lot of notes on adjustment and I have the MF27 manual but I do not have a pressure guage.

Mike.