I bought a new MF-135 about a month ago and today I purchased a Bush Hog Freeman 3000 Loader that was on a MF-165, but was previously on an MF-135. I am in over my head here, but I figure that is the only way you learn to swim so please help me out.

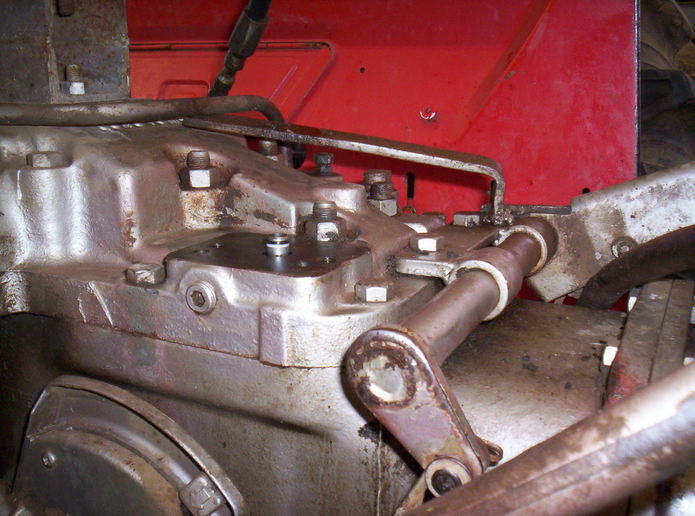

My MF-135 current has one Hydraulic Hookup that I can see. Based on other posts and pictures I believe this to be a return hookup but not sure.

The Bush Hog Freeman 3000 Loader needs to Hydraulic Hookups. Not sure if I have two and if I do, where are they?

The loader does have the controls to raise and lower the bucket and to dump it using hydraulics.

I am attaching a picture as to what I see, can you point me in the right direction. The hose coming off the hydraulic line is currently not attached to anything.

Thank You,

Stuart

My MF-135 current has one Hydraulic Hookup that I can see. Based on other posts and pictures I believe this to be a return hookup but not sure.

The Bush Hog Freeman 3000 Loader needs to Hydraulic Hookups. Not sure if I have two and if I do, where are they?

The loader does have the controls to raise and lower the bucket and to dump it using hydraulics.

I am attaching a picture as to what I see, can you point me in the right direction. The hose coming off the hydraulic line is currently not attached to anything.

Thank You,

Stuart