495man

Well-known Member

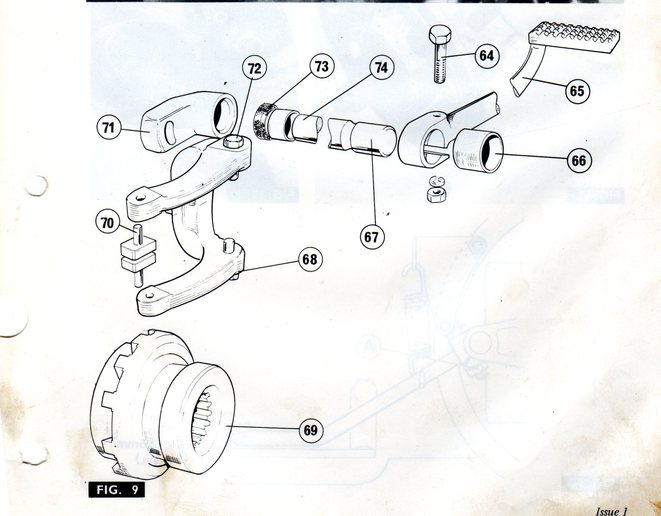

Ok MF experts, I've been trying to get the diff lock working on the 240, I asked about this one other time and here is where I am at:

It worked great a few years back, I parked the tractor inside for the winter, and went to use the lock the next spring and it won't "lock"

It hasn't worked in a few years and I'm finally getting around to it.

While it was still working I had adjusted the pedal height when engaged to be what the manual stated as before the pedal would touch the floor board when engaged.

The pedal is tight on the splined shaft, and moves up and down slightly while rotating the shaft slightly, and the shaft will move in and out slightly in the housing, I can stand with my body weight on the pedal while driving and it will not drop in to lock(weaving slightly while driving slowly forward (Low 1st) to try and get the axle halves aligned the same way when the lock was working)

I've had the tractor parked on a slant for 4 weeks now with the right rear wheel up on a tall block trying to get penetrating oil to work it's way in.

Am I to the point this problem is internal? or should I keep trying what I'm doing and hope it will eventually "come free"

I have the service manual but am not looking forward to taking the trumpet housing off, and likely won't in the immediate future.

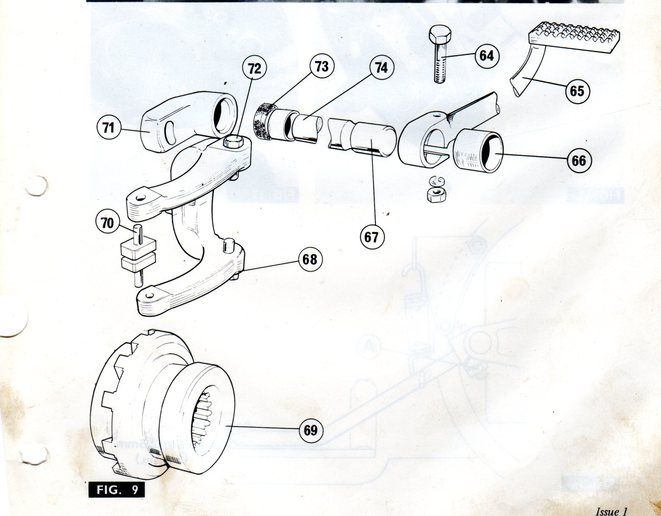

It worked great a few years back, I parked the tractor inside for the winter, and went to use the lock the next spring and it won't "lock"

It hasn't worked in a few years and I'm finally getting around to it.

While it was still working I had adjusted the pedal height when engaged to be what the manual stated as before the pedal would touch the floor board when engaged.

The pedal is tight on the splined shaft, and moves up and down slightly while rotating the shaft slightly, and the shaft will move in and out slightly in the housing, I can stand with my body weight on the pedal while driving and it will not drop in to lock(weaving slightly while driving slowly forward (Low 1st) to try and get the axle halves aligned the same way when the lock was working)

I've had the tractor parked on a slant for 4 weeks now with the right rear wheel up on a tall block trying to get penetrating oil to work it's way in.

Am I to the point this problem is internal? or should I keep trying what I'm doing and hope it will eventually "come free"

I have the service manual but am not looking forward to taking the trumpet housing off, and likely won't in the immediate future.