graveldog25

New User

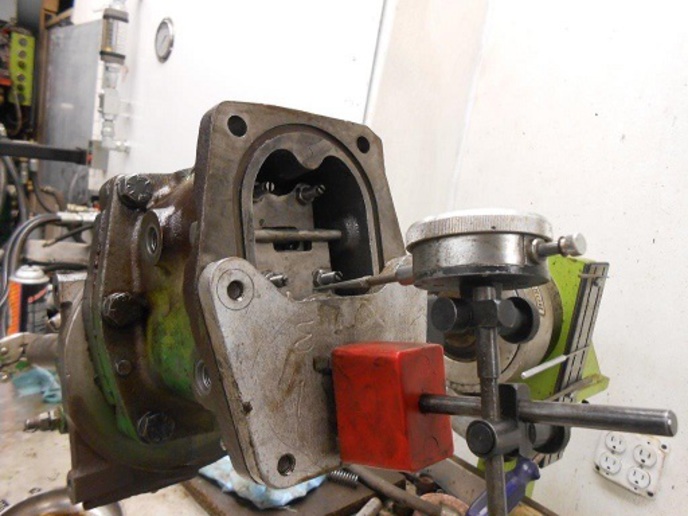

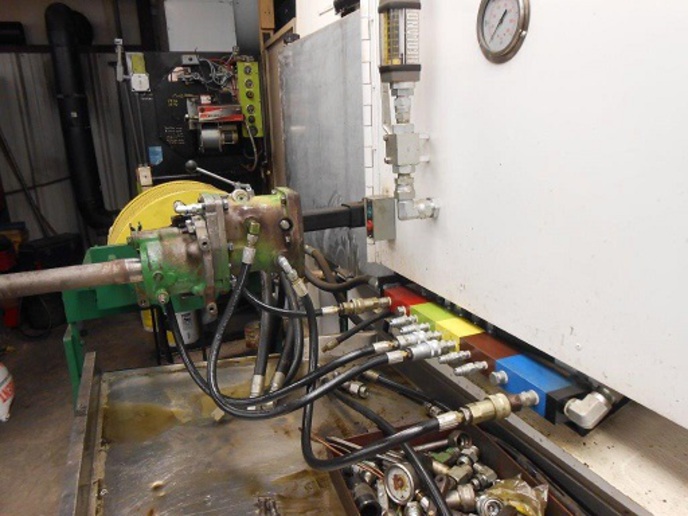

I have a steering valve apart that the guy said was leaking oil out under steering wheel. Disassembled unit and found orings were rotted away. Resealed complete unit and set valve levers with the John Deere plate. I hooked unit to a tractor to test with the prodedure for the late model 4020. Tractor is newer and has higher pressure rating, but I put a tee in line so I could bleed down to the recommended pressure. When I apply hydraulics to the valve the return from the steering valve flows like crazy. I have the tractor at zero flow and slowly open it. No matter how far I open the tractor valve, it looks like all of the oil is running out the return. I took the steering valve apart and rechecked my work and dont see anything wrong. I powered the valve with the bottom cover off and the oil is coming out of the relief valve. When I did this, I had the steering valve levers out. Can anyone out there offer some insight as to what I have going on here?