Johndeere630farmer

New User

I have a John Deere 630 Gas that is losing oil out of the crankcase.It runs great and has no oil burning issues just after about 4 miles of driving the oil level gets down to the middle mark between 2 quarts and full.

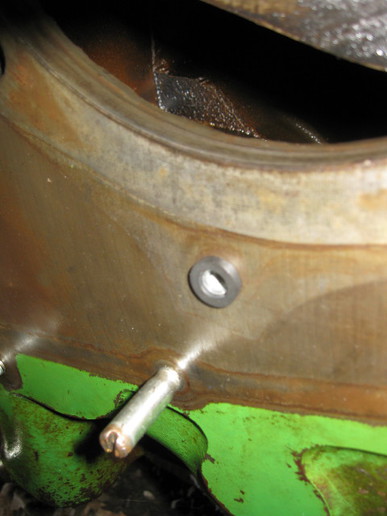

Idk if this problem is the pulley side main bearing seal or the ventilation pump. It does drip motor oil on the inside lip of the clutch. There seems to be alot of crankcase pressure because when this bolt for the

flywheel cover that is drilled all the way into crankcase is off it blows out with a little oil and alot of pressure and this is at the top of the crankcase. Wondering if someone could point me towards the issue.

Idk if this problem is the pulley side main bearing seal or the ventilation pump. It does drip motor oil on the inside lip of the clutch. There seems to be alot of crankcase pressure because when this bolt for the

flywheel cover that is drilled all the way into crankcase is off it blows out with a little oil and alot of pressure and this is at the top of the crankcase. Wondering if someone could point me towards the issue.