There is a hydraulic fluid leak at the pin that connects the draft link, on both sides.

To make sure I found the correct place where the hydraulic fluid is leaking, I removed the draft link (please see picture) - indeed, the oil is coming around these pins.

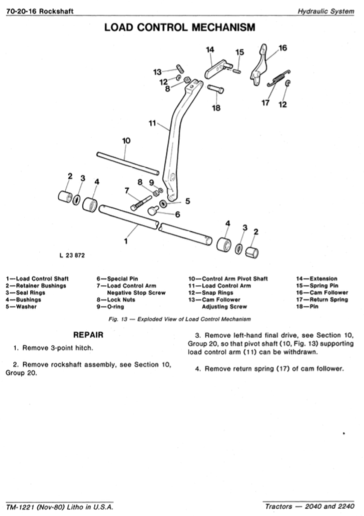

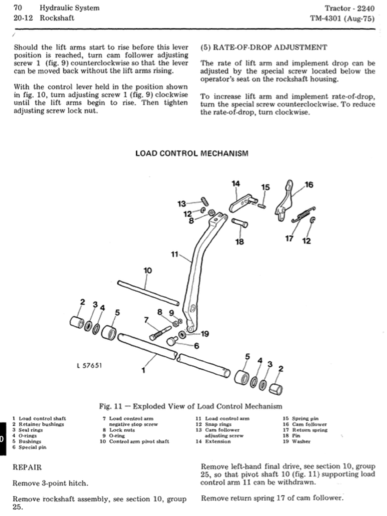

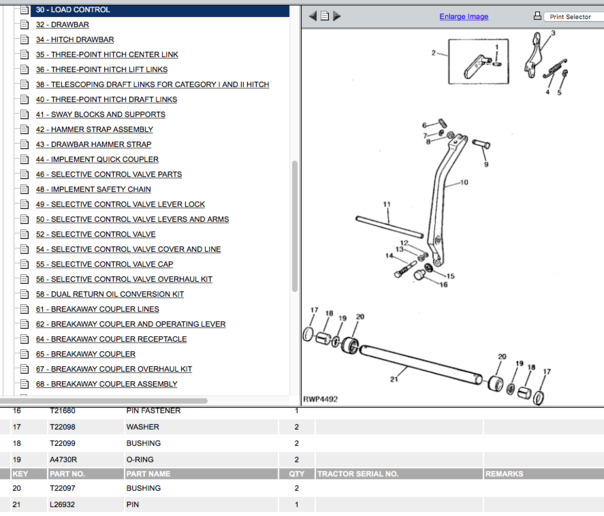

I looked in the on-line JD parts catalog but did not find information about these pins (well, I looked almost anywhere, but failed to find them). I suppose there is a seal on the inside of each pin.

I would appreciate any suggestions that would help fix this leak.

Thank you,

Paul

To make sure I found the correct place where the hydraulic fluid is leaking, I removed the draft link (please see picture) - indeed, the oil is coming around these pins.

I looked in the on-line JD parts catalog but did not find information about these pins (well, I looked almost anywhere, but failed to find them). I suppose there is a seal on the inside of each pin.

I would appreciate any suggestions that would help fix this leak.

Thank you,

Paul