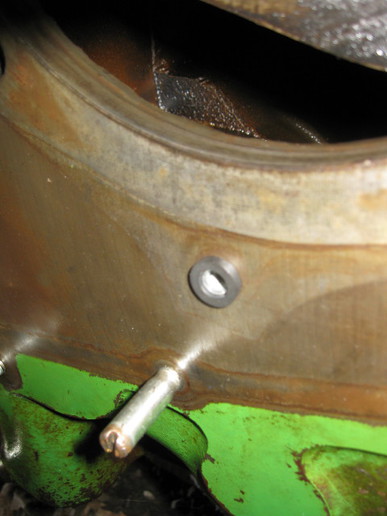

Engine used to run great. It has sat 10 years. It looks like the last time it was run the crankcase was full of gasoline and cleaned everything up. It will only turn over with excessive help with wheel and clutch bolt with bar. Removed Pistons. Still almost impossible to tun the crank over. Seems bearings are dry, I see no rust.

Do any of you have any ideas that would help free the crank shaft up. Every thing inside is very clean and dry No Rust.

Thanks

Do any of you have any ideas that would help free the crank shaft up. Every thing inside is very clean and dry No Rust.

Thanks