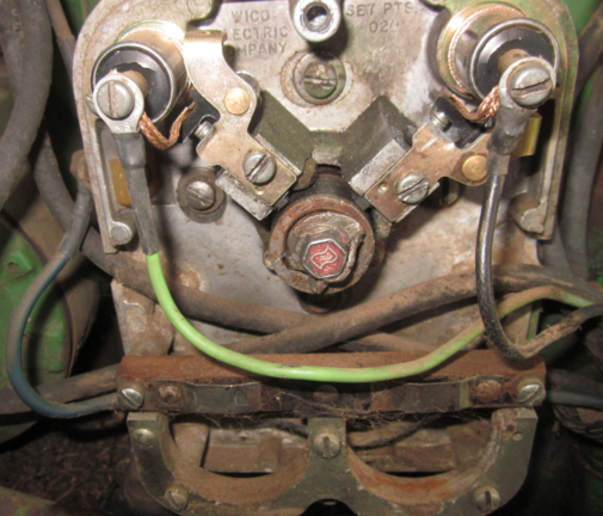

I don't want to deal with these darn coils anymore. Does anyone have experience using individual 6 volt coils to run the pony motor?

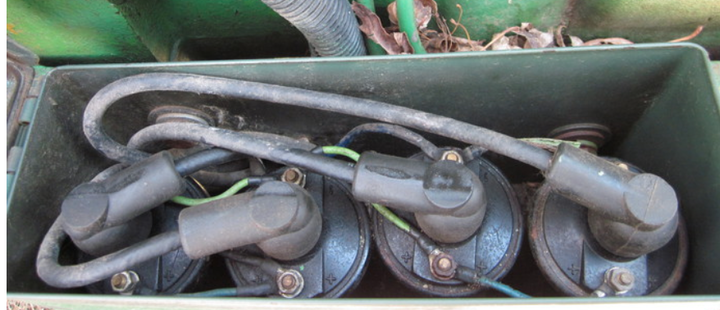

I saw on this board one time ago a picture of 4 coils in a box attached to the side of the tractor with spark plug wires running to each plug. My question is, can someone send me a wiring diagram on how I would wire it up if using 4 separate coils, and can you use any 6 volt car coil, or do they have to have a certain type of rating?

I saw on this board one time ago a picture of 4 coils in a box attached to the side of the tractor with spark plug wires running to each plug. My question is, can someone send me a wiring diagram on how I would wire it up if using 4 separate coils, and can you use any 6 volt car coil, or do they have to have a certain type of rating?