Although I have done searches on this and other forums, I want to make sure I have this correct.

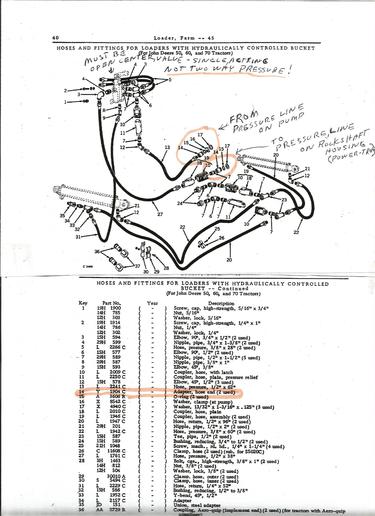

I want to add a single spool valve to my 70D to control the loader hydraulics (just the one set of cylinders, no power bucket), leaving the Powr-Trol to operate the rockshaft.

I am getting a 4-position valve with power beyond capabilities. I will plumb the pressure line from the pump into the spool valve, the power beyond will go to the pressure side of the Powr-Trol and the output will T into the return line to the pump.

I'm afraid I still don't understand the power beyond, is above the correct application for it? I don't need to operate both the loader and the 3-point at the same time. Is it okay to T the spool return into the return line from the Powr-Trol? Has anyone done this before and have pictures about where/how they mounted the spool valve?

Thanks.

I want to add a single spool valve to my 70D to control the loader hydraulics (just the one set of cylinders, no power bucket), leaving the Powr-Trol to operate the rockshaft.

I am getting a 4-position valve with power beyond capabilities. I will plumb the pressure line from the pump into the spool valve, the power beyond will go to the pressure side of the Powr-Trol and the output will T into the return line to the pump.

I'm afraid I still don't understand the power beyond, is above the correct application for it? I don't need to operate both the loader and the 3-point at the same time. Is it okay to T the spool return into the return line from the Powr-Trol? Has anyone done this before and have pictures about where/how they mounted the spool valve?

Thanks.