As I'm working in the woods on my property this winter I'm reminded about a lack of traction on the steep terrain in my corner of Illinois. I've been cutting some trees; mostly for firewood and needing to drag some logs and tree tops up out of my woods. I've never had a crawler tractor before, but I'm thinking that something like a 40C-420C-430C or perhaps even newer like a 1010 would work for my purposes. Of course for earth moving a reverser would be nice, but probably not a must.

As far as tracks go, I would guess I would need grousers rather than regular (and less aggressive) tracks.

I'm a little bit torn about looking for one equipped with a loader versus a blade.

Since I"m not setup to work on undercarriages I'm going to have to look for something that doesn't need any major work or repair...essentially I want to find something usable for this season and that has had some work done to it in recent memory.

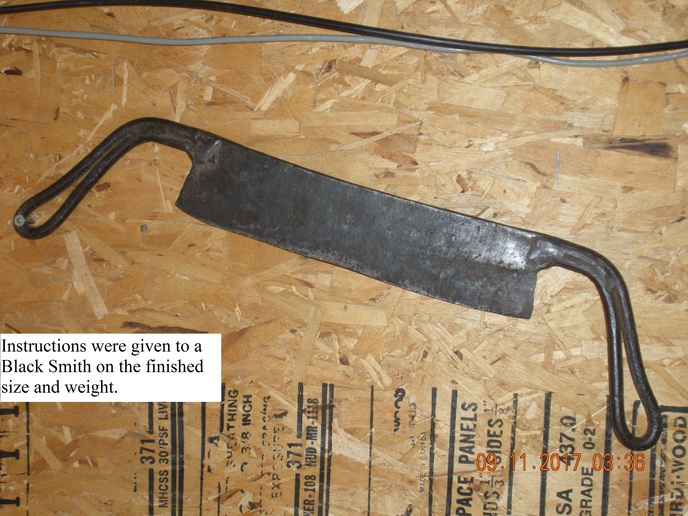

I've seen a few in the past with cable winches on back...that would be pretty useful for skidding trees & logs, but I'd want a drawbar too for hooking up a moldboard plow on occasion.

Any suggestions would be welcome...and yes budget is important as I don't want to mortgage the farm to buy one.

Tyler in IL

As far as tracks go, I would guess I would need grousers rather than regular (and less aggressive) tracks.

I'm a little bit torn about looking for one equipped with a loader versus a blade.

Since I"m not setup to work on undercarriages I'm going to have to look for something that doesn't need any major work or repair...essentially I want to find something usable for this season and that has had some work done to it in recent memory.

I've seen a few in the past with cable winches on back...that would be pretty useful for skidding trees & logs, but I'd want a drawbar too for hooking up a moldboard plow on occasion.

Any suggestions would be welcome...and yes budget is important as I don't want to mortgage the farm to buy one.

Tyler in IL