RedBarnNate

Member

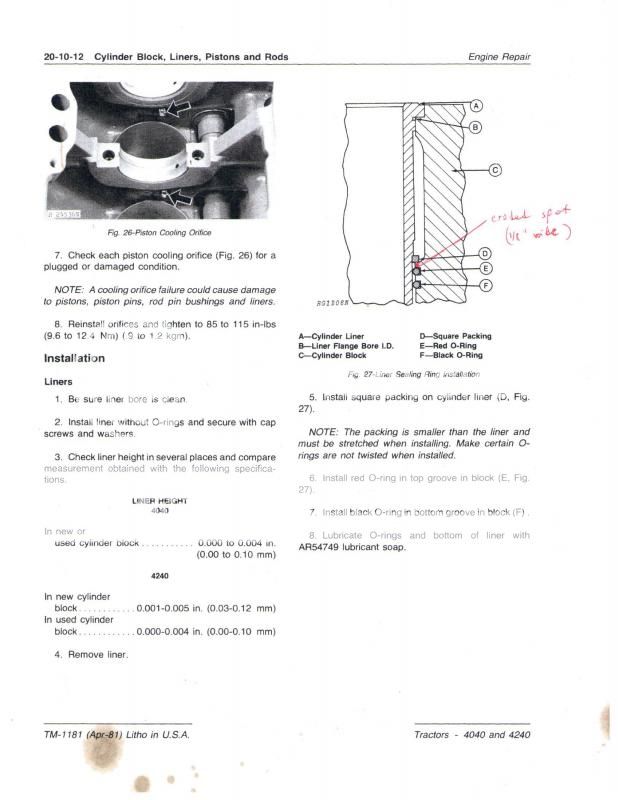

Hello community! We are part way through an in-frame engine rebuild on a John Deere 6-404 6-cylinder diesel engine. My mechanic notified me that he found some pitting or chips missing in the o-ring groove of at least one hole.

This 4040 tractor will continue to be worked after the rebuild. It spends 6-7 days a week feeding cows on a dairy.

Can anyone with prior experience chime in with recommendations? I'm not comfortable with continue the rebuild before addressing this issue. I have a couple ideas in mind, but would like input from others that have traveled this road before.

This 4040 tractor will continue to be worked after the rebuild. It spends 6-7 days a week feeding cows on a dairy.

Can anyone with prior experience chime in with recommendations? I'm not comfortable with continue the rebuild before addressing this issue. I have a couple ideas in mind, but would like input from others that have traveled this road before.