carvel minne farmer

Well-known Member

good evening guys I am going to look at a I.H. manure spreader one of my neighbors has, (when it drys up here) we where talking at a local hall function and he's retired from farming and has his land rented out. he was telling me it's in nice shape just needs new plywood floor. I am thinking about an idea I had a few years back but didn't do it (wasn't my spreader) of putting in the new plywood floor and then putting 1/4" poly puck board on top of the plywood. for you guys that aren't hockey fans puck board is a white plastic (poly) comes in 4' x8' sheets and is used to line the inside of the boards in hockey rinks. one side is very smooth and slippery, and the other side has a rougher texture to it (for gluing).

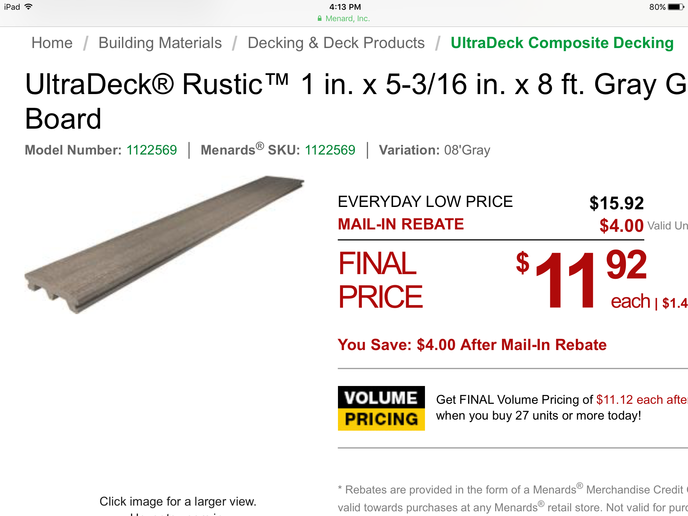

my question: would the smooth slippery surface work better for unloading the manure? the chains and cross bars should move smoother and not have as much drag on the slippery puck board. going with 3/4" pressure treated and then the 1/4" puck board on top.

thoughts on this and has anyone done this?

my question: would the smooth slippery surface work better for unloading the manure? the chains and cross bars should move smoother and not have as much drag on the slippery puck board. going with 3/4" pressure treated and then the 1/4" puck board on top.

thoughts on this and has anyone done this?