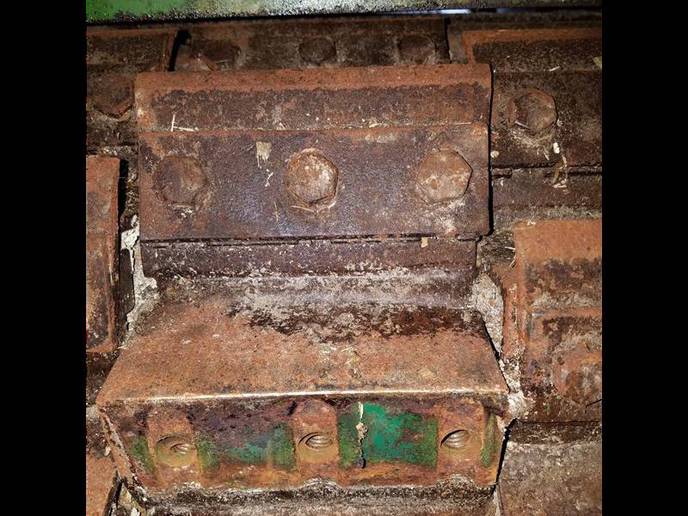

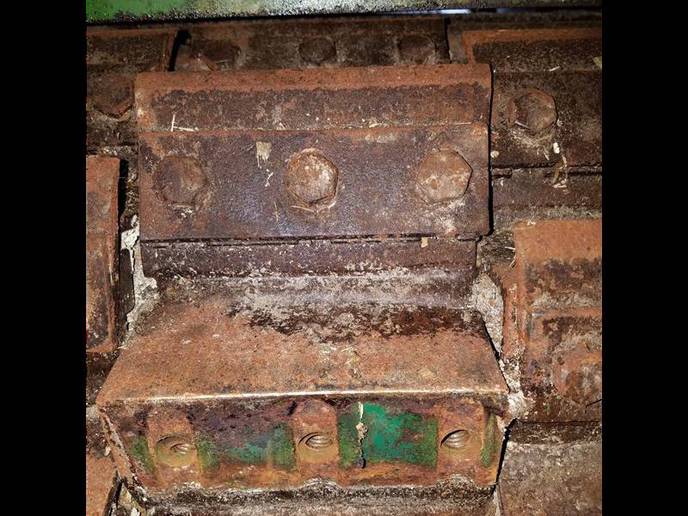

I ran out of stationary knife travel on our 3960 silage chopper, so I need to either set the old cutterhead knives out, or put on new knives. How much wear is too much to reuse the knives? Attached is a picture showing a new knife next to one that came from the cutterhead. Attached is also a picture of the knives as they currently sit on the cutter drum.

I do not know what to do, as there is still a good bit of hard facing left on the knives, but if I move them out much, the knife hold-down plate will lap over beyond the bottom edge of the knife, and will not have as much contact area with the knife to hold it in place.

We do not chop a lot of corn silage, as the wear you see is from at least 15 years of use.

Thank you for any advice!

I do not know what to do, as there is still a good bit of hard facing left on the knives, but if I move them out much, the knife hold-down plate will lap over beyond the bottom edge of the knife, and will not have as much contact area with the knife to hold it in place.

We do not chop a lot of corn silage, as the wear you see is from at least 15 years of use.

Thank you for any advice!