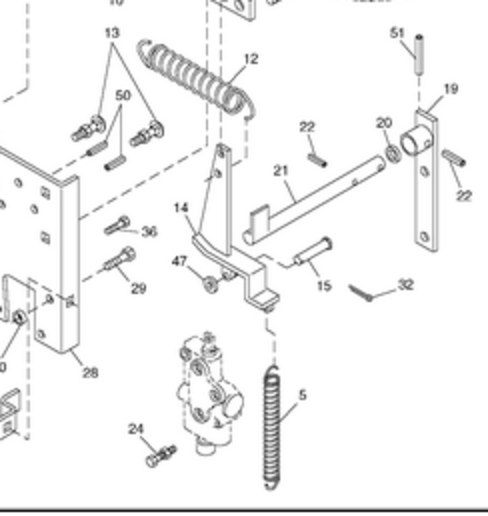

Having problems with my baler. The tying system will not reset. It will not wrap automatically or manually. The only way to get the system to wrap is to climb off the tractor and run around the baler with a couple wrenches to manually pry up the piston. The piston needs to be held the entire time the wrap system is working.

The piston I am talking about is in the unit at the end on the lines on the right.

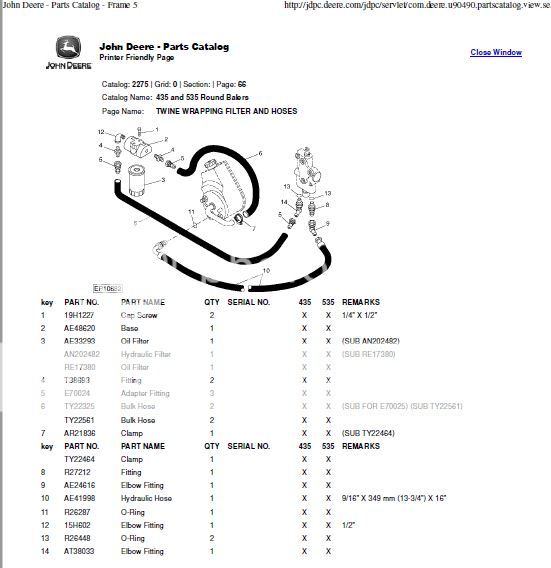

Pump has <300 bales and the filter about 125.

Unfortunately JD has changed their pics online and I'm not where I can get to my manuals to scan a more complete picture of the mechanism.[/img]

The piston I am talking about is in the unit at the end on the lines on the right.

Pump has <300 bales and the filter about 125.

Unfortunately JD has changed their pics online and I'm not where I can get to my manuals to scan a more complete picture of the mechanism.[/img]