Dan in North Houston

Member

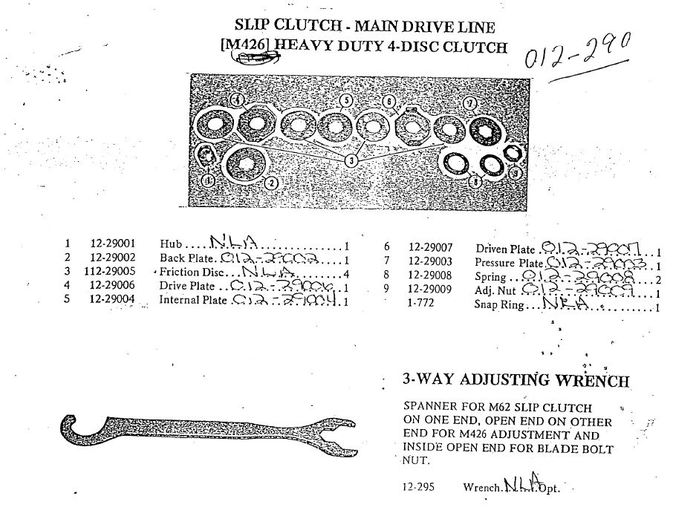

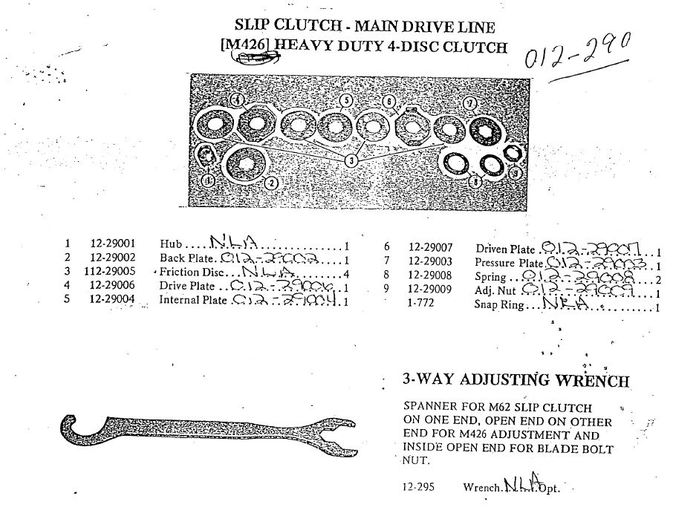

Mohawk batwing shredder, probably a model 1360, and probably around a 1980's model. It works fine, but I've never seen slip clutches like this. Was able to get a parts manual from Ag-Meier but no owner's manual. Clutch adjustment is by rotating the big nut next to the gear box to put pressure on the clutch disks. The nut would take a wrench of about 3 or 4", and the parts manual shows an adjusting wrench that is no longer available. From the size of the nut, the length of the wrench is probably 2 or 3 feet long. And of course, there's not much space to get a wrench in there, so a pipe wrench would not work. Will have to make a wrench out of plate steel if I ever need one.

I understand how it works, but how to set the proper adjustment? Trial and error? I realize that I can just keep tightening until it doesn't slip, but would appreciate any tips if anyone has dealt with this before.

I understand how it works, but how to set the proper adjustment? Trial and error? I realize that I can just keep tightening until it doesn't slip, but would appreciate any tips if anyone has dealt with this before.