It sounds like you have an inspection hole with a cover, lined up with the blade holder or stump pan, so you can get a socket onto the top side of the fastener used to hold the blade. Its possible that you have a shear type shoulder type bolt with a nylon lined nut in in there, but given there are so many of these kinds of mowers, I'm just taking a guess on that, but if so, beware, those can or may be left hand thread.

I often do like Zach says, but leave it connected to the tractor, raise it up onto 2 6x6 hardwood blocks, each side perpendicular (4 total), just in case one was to roll, the mower can't easily fall off those blocks which again are just one high. You can disconnect the pto, pull your coil wire, battery cable etc. to be safe, chock the tractor wheels, leave in gear or use brake pedal if its got the rear brake lock, possible a 641 one may have one, many do not.

At that point, you can lay on a creeper or for more room, cardboard, and reach in, move the blades around to where you can reach them with a 4" grinder to sharpen, you may not have the most amount of room, but those 6" blocks will give you a lot more room to work then not. It can be hard to get the angle on the blade you want to sharpen it, on mine I can do a decent job this way, but have taken them off to sharpen while I'm servicing it anyway.

For blade removal, you can get a socket and breaker bar from one side, 3/4 would be nice, but I use a 1/2" as that's what I have. On the bottom side it could be an oval shaped head, with flat sides, an adjustable wrench will fit on and hold it. Its best done with 2 people if this is the type, but I always end up doing this alone and can deal with it accordingly. You can use a cheater pipe for the handle of each tool and straddle the mower on the ground, or like me, I'll hoist it with a loader and work on it standing up, but leaning against something immovable or solid, and I work using those cheater pipe extensions staying OUT of its path if it were to fall over, which is not likely as I keep the chain hooked to it the entire time. Like this I can stand and work each tool. Either way, with mine I have to straddle that deck, flat to the ground, up side down or on its side. I welded a hook to the deck to make it easy to pick and stand up.

Some bolts are round with a tang on each side, that hold like a carriage bolt, so all you may have to do is turn the nut from the top side, beware of left hand threads. So see what you have on the bottom, its could be easier and you just need to spin the nut. You may be able to jam something in the drive line/shaft end yoke or the blade holder to keep it still. Just don't use a huge cheater pipe and put a lot of force on it, at that point I'd replace the blade bolts, and remove with a cutting torch.

Now that's just me, don't do anything you are not comfortable with, and always be safe in what you do, never stand under something like this. When I sharpen the blades from the ground, my hand and arms are the only thing that go under the deck where it discharges the cut material, so it if it fell its not a direct hit that will crush or cause serious injury.

If you take the blades off, you can do a better job to sharpen them in my opinion, and you can check the blades for equal weight, as they should be balanced anyways.

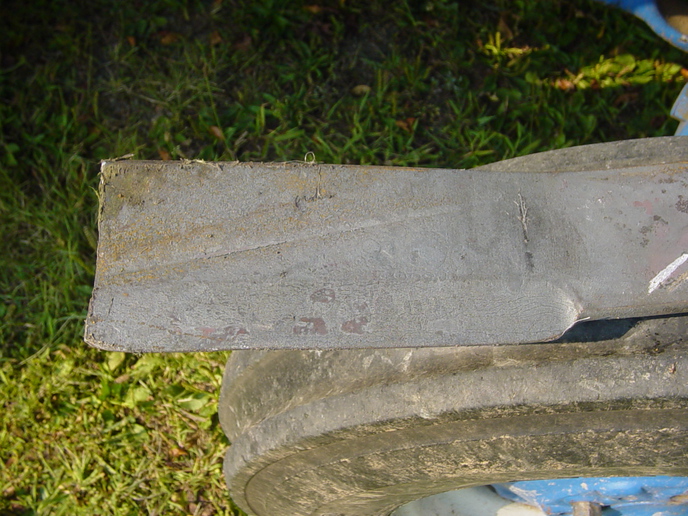

Some will say sharp like a knife blade for grass and thin weeds, and blunt for thicker vegetation, if you look at a new blade in section, you can see its flat on the edge, not a point. See the photos, and note what the new ones look like.

Take the time to read your manual, for service, repairs and proper adjustment to the tractor. The mower should be level side to side, and the front should be tilted down, say an inch or just bit more lower than the back, doing this, new or sharp blades, will make it cut as efficient as possible, you will notice the difference in both performance and the job it does.

Grass and weeds won't dull these blades very much on limited use, but if they are well worn, deformed, beat up, or otherwise, it is time to replace them. Rocks, steel junk or similar things run through it will damage or gouge blades, so its best to keep that mower up high and know the work areas/fields to avoid hitting things like these.

If this one is only 3 years old and you have not hit anything with it, the blades should be in nice shape. New blades are nice and will be balanced, if they are questionable, you can't go wrong with new, I ran old deformed ones one season for awhile, new ones and proper adjustment allowed me to cut in the next highest gear, speeding things up and it did a great job, it made all the difference.

Hardware in the photo is a shoulder type bolt, a shear type, with a nylon lined nut and it has LEFT hand threads.

Blade Bolts